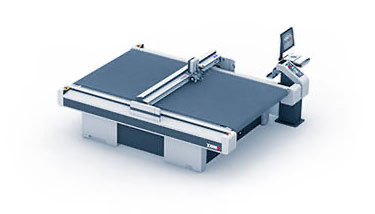

G3 Digital Cutter

Uncompromising performance and precision

Intelligent. Efficient.

Ready for the future!

Quality at the highest level

The G3 Cutter is a precision machine. From innovative drive system to blade, all components are perfectly coordinated. Produce your jobs at the highest quality level, economically and efficiently. Your customers will be thrilled with the results.

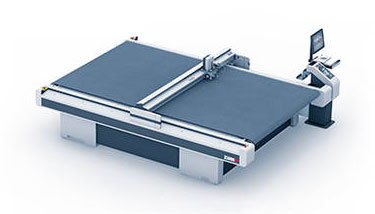

Modular design for maximum flexibility

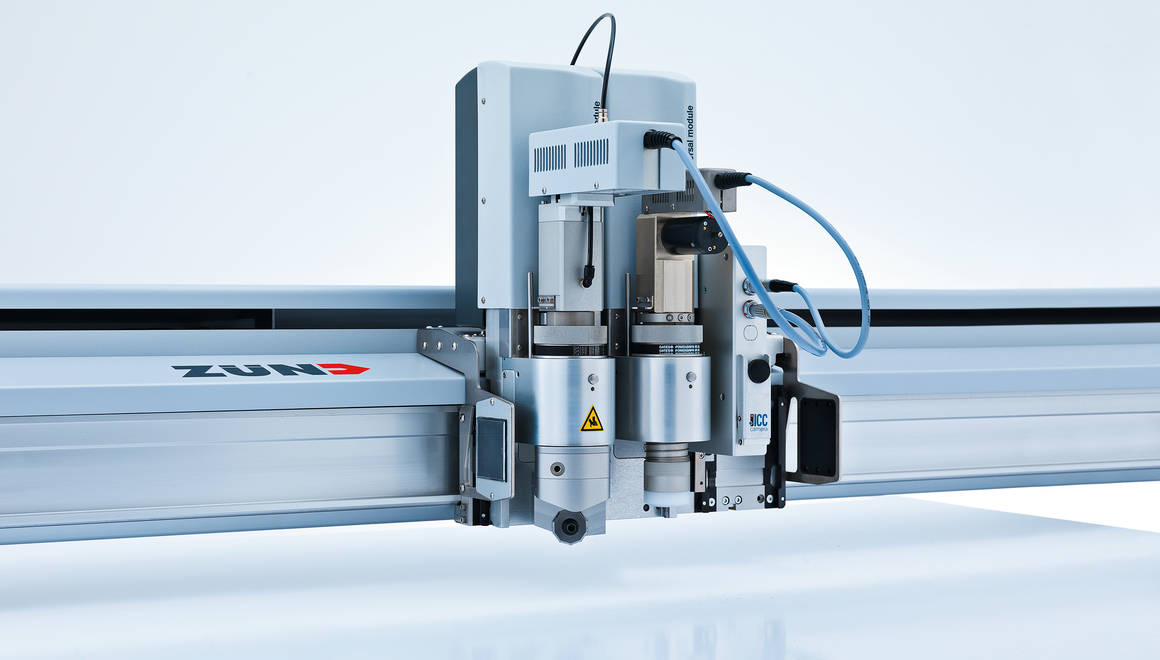

The extraordinary modularity of our cutting solutions is truly unique. You can always make your G3 cutting system adapt to new requirements with modifications and upgrades. Zünd cutters are a safe investment and offer maximum value retention. Zünd’s modular design concept lets you put together a tailor-made cutting solution configured to meet specific production needs.

Unsurpassed price-performance ratio

The price-performance ratio of the G3 cutter series is outstanding. We use only the most modern technologies and highest-quality components. The flexibility, reliability, and quality of the G3 cutter cannot be matched by any competitor.

Maximum productivity

The overall productivity of the G3 cutting system is unrivaled. We achieve this through the use of intelligent control technology, robust machine components, and sophisticated cutting technology. All components are perfectly coordinated.

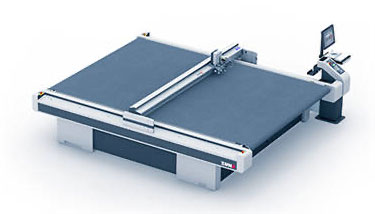

Perfection in every detail

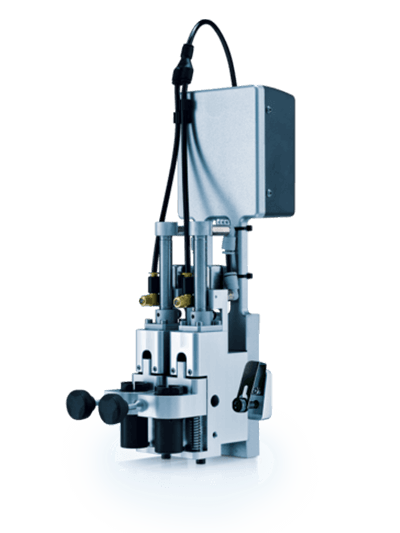

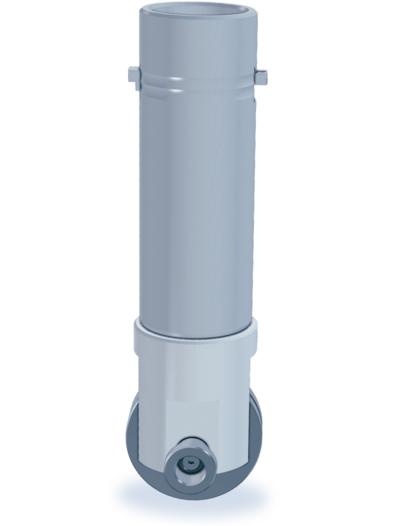

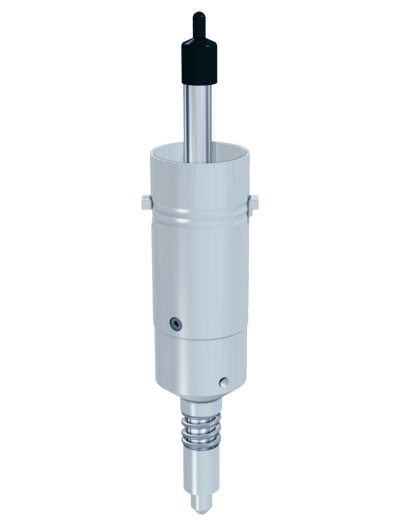

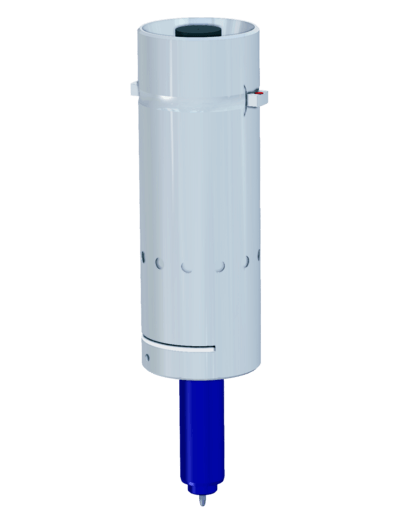

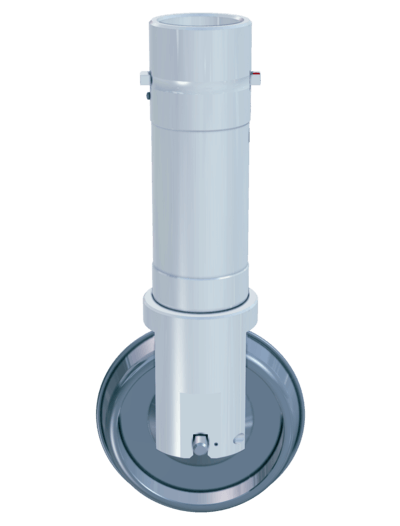

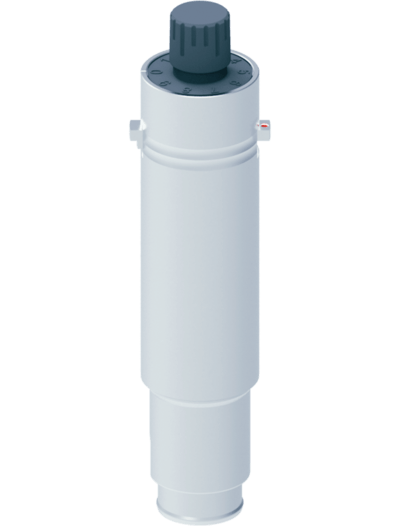

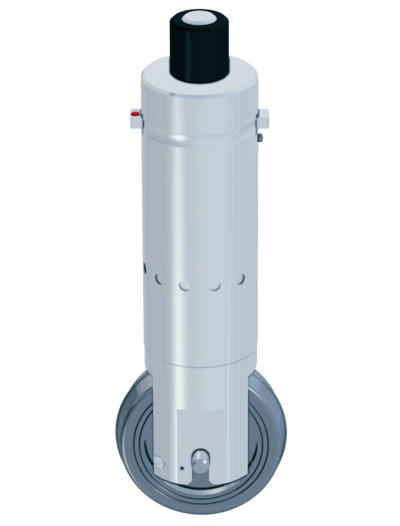

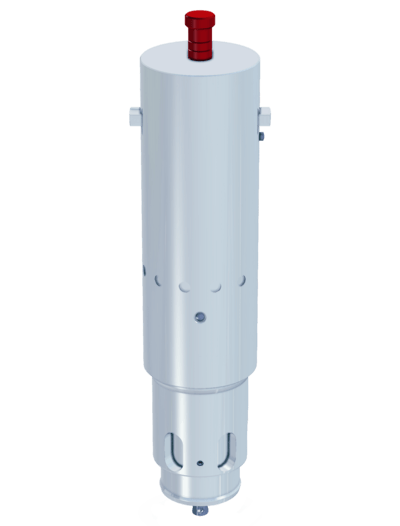

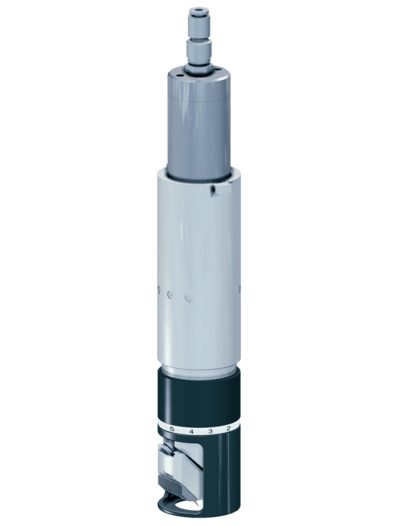

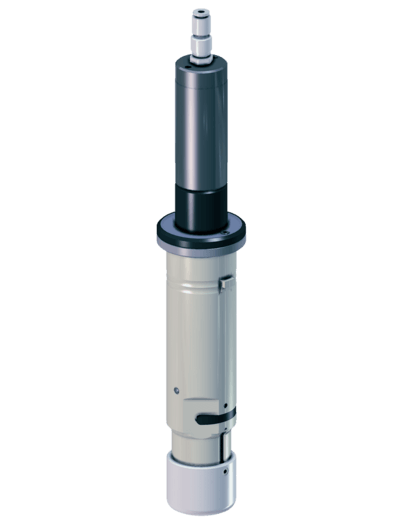

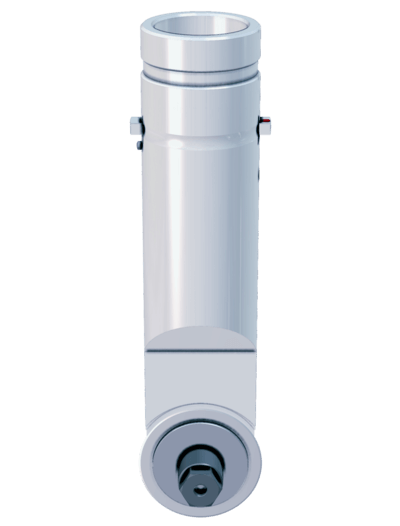

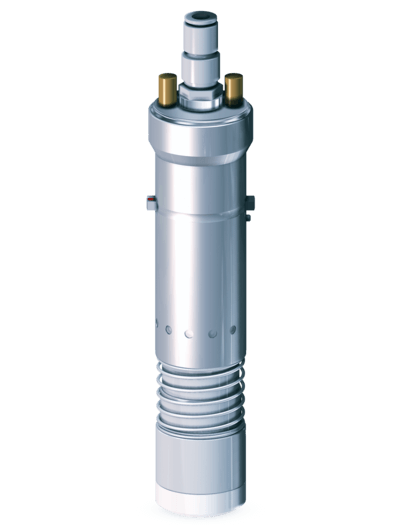

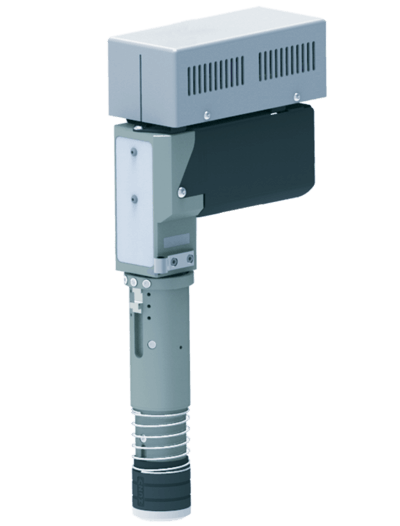

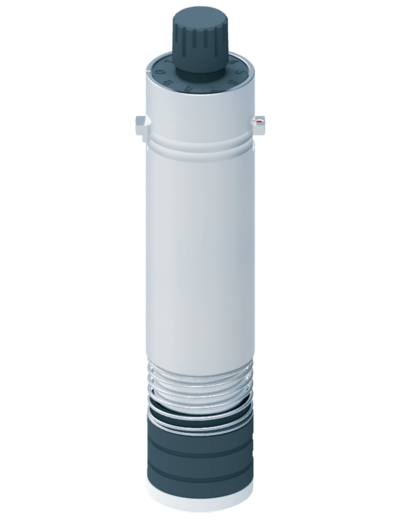

Define which functions your G3 cutter has to perform and configure your modular Zünd tooling accordingly.

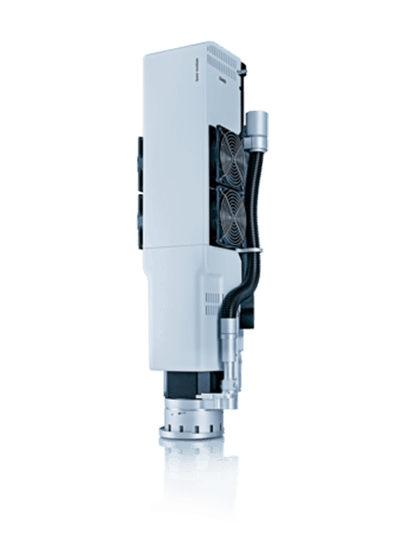

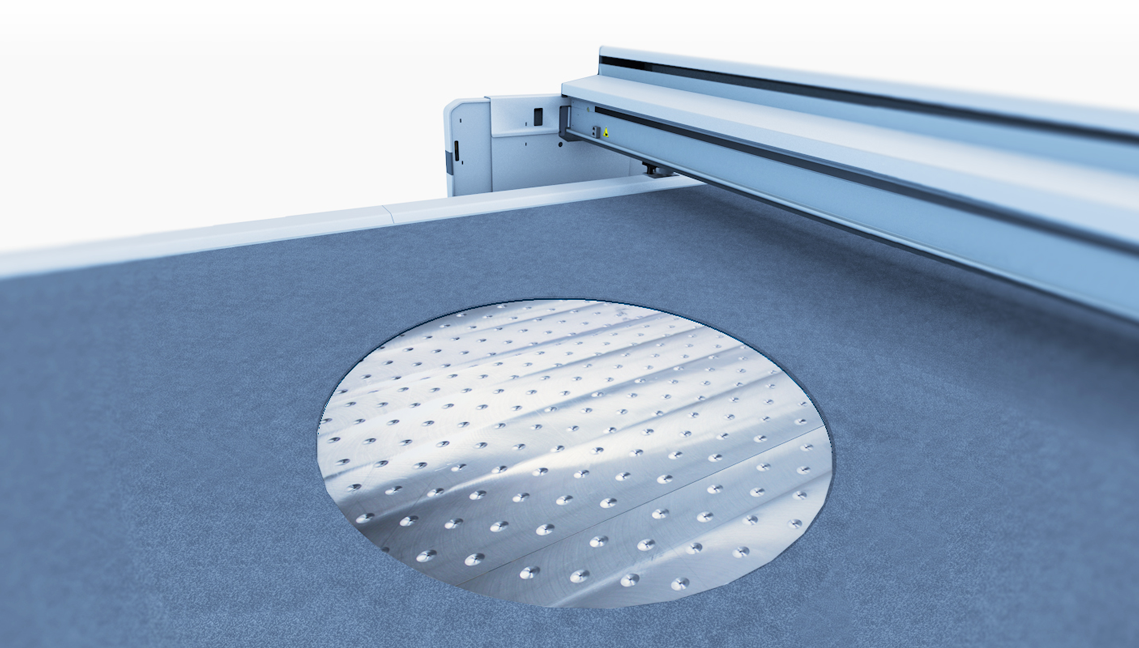

Energy-efficient vacuum turbines ensure reliable material hold-down during the cutting process. The vacuum area is divided into zones, which can be switched on and off individually across the width of the machine.

The setup of of knife-cutting, routing, and creasing tools occurs fully automatically. The ITI Initialization System makes the process quick and precise.

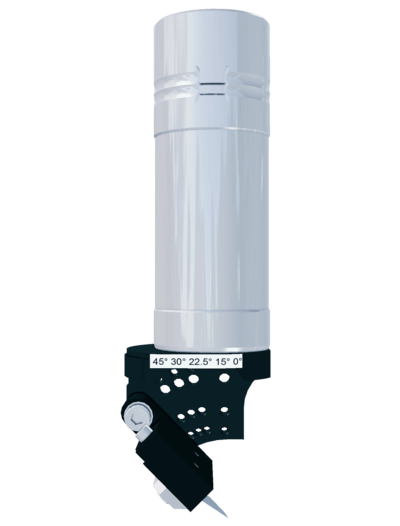

On a G3 cutting system, you can process materials up to a thickness of 110 mm/4.3 in. Depending on your requirements, the G3 can be configured with a beam height of 30, 60 or 120 mm/1, 2 or 4 in. This means more flexibility and versatility in your production workflow.

Configure the D3 according to your specific needs, with cutter extensions and/or material-handling solutions. Just like the cutter, all these options were designed with an eye towards ergonomics. The cutter is easily accessible from all sides, which ensures an efficient production workflow.

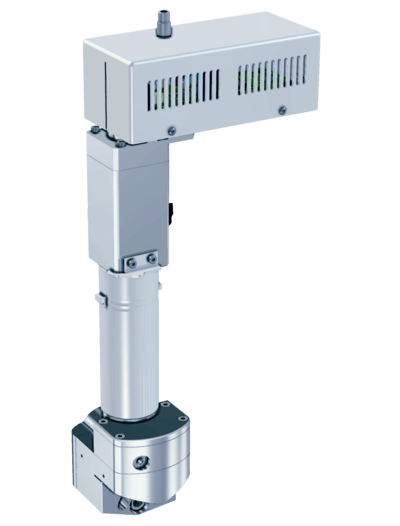

Automate picking and sorting of cut parts with a collaborative robot. This enhances the level of automation of your cutting solution and increases productivity. The collaborative robot requires no guards or protective devices.

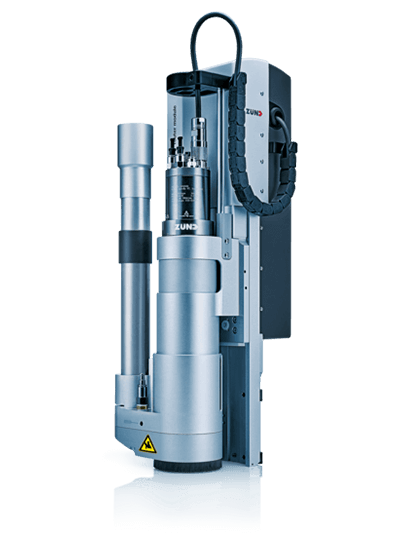

The automatic router bit/tool changer ARC dramatically reduces set-up times and simplifies tool handling. The magazine can accommodate up to eight different cutting, polishing, or engraving bits. The bits needed for processing are automatically removed, clamped, initialized, and cleaned after each use. The ITI initialization system checks the zero point after each tool change, ensuring perfectly consistent routing depths.

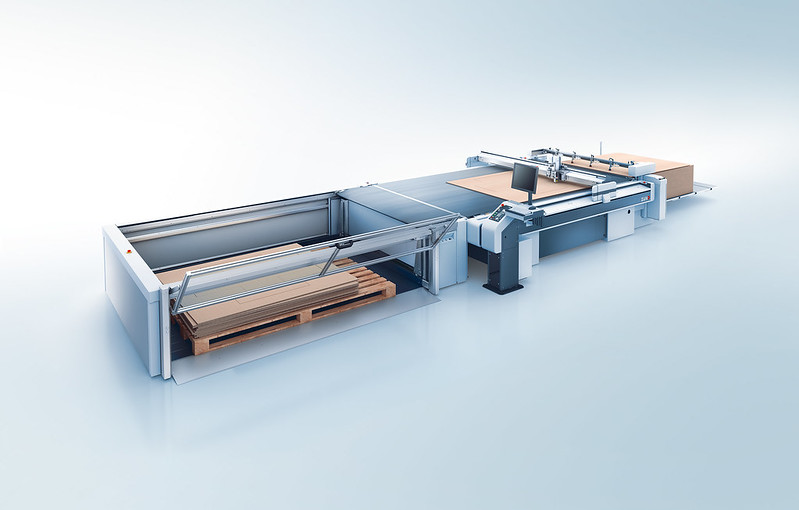

Cut from the backside Board-loading extension with UNDERCAM

The Board-Loading Extension with UNDERCAM automates loading of rigid materials and ensures precise cutting with its registration system. By reducing manual work and streamlining material handling, it increases efficiency, speeds up production, and maintains high cutting accuracy.

Modular cutter concept

With modular tool and material-handling systems, you can tailor your G3 cutter to your specific requirements. Zünd’s modular design concept lets you customize your cutting solution according to your specific production requirements.

Modular, flexible, and adaptable

Reliable and productive – Zünd high-performance modules

Ingeniously versatile

The Zünd tool concept.