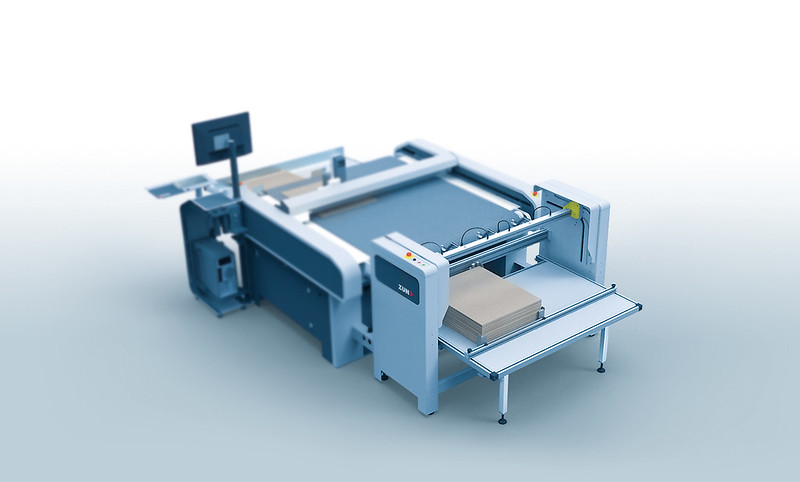

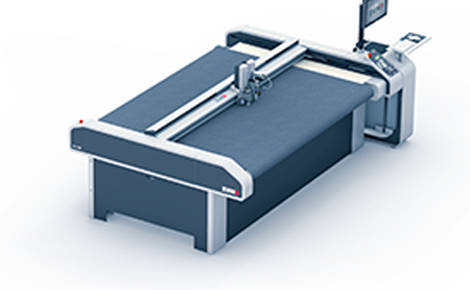

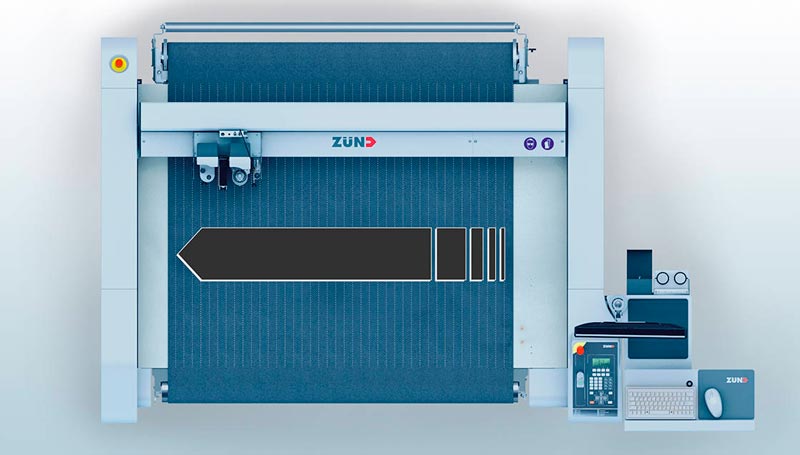

S3 Digital Cutter

Compact, flexible, and economical

Speed through smart technology

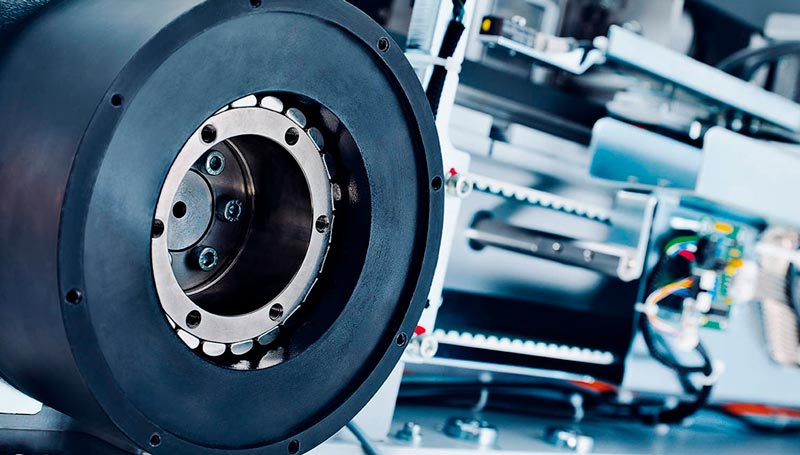

The S3 digital cutter is fast. The basis for the S3’s outstanding productivity are intelligent control software, a fast drive system, and cutting technology perfected over many years. Zünd tools optimally designed for use on the S3 complete the system.

Adaptable production processes

S3 multi-functional cutting system allows for many and variable cutting processes. With the addition of sophisticated material-handling solution, you can increase production capacity many times over.

Best price-performance ratio

The price-performance ratio of the S3 cutter series is excellent. Only the most modern technology and highest-quality components are used. The flexibility, reliability, and quality of the S3 cutter cannot be matched by any competitor.

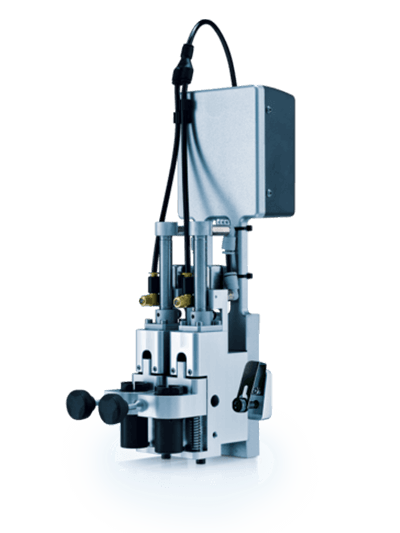

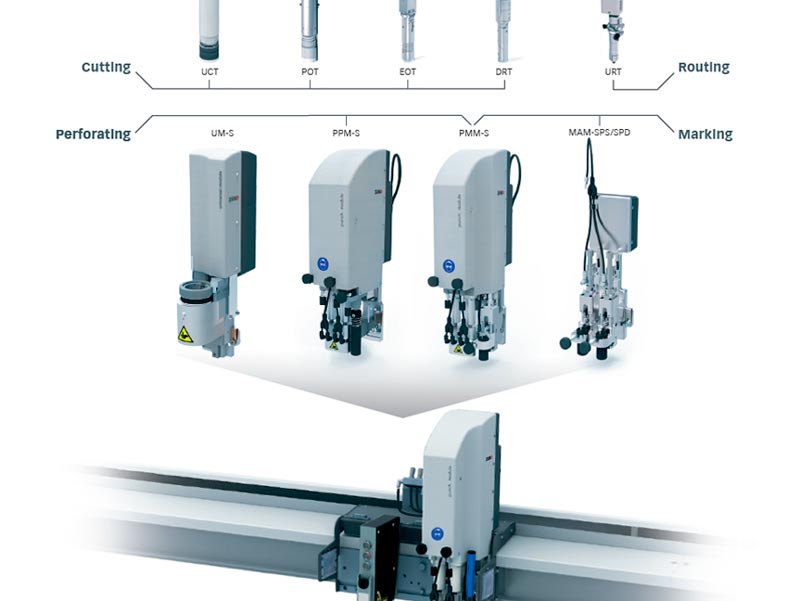

Modular, efficient, flexible

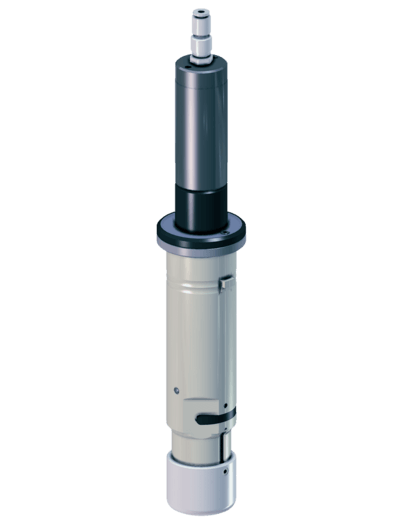

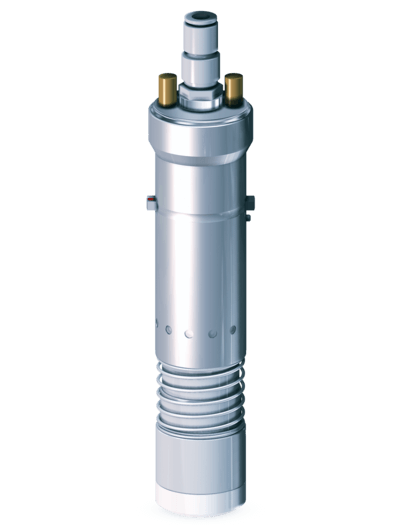

You have the flexibility to choose precisely the tools you need for the job at hand. Combine the required tools based on your specific requirements. You can equip the S3 with up to two different tools.

The S3 cutting surface is made of acrylic. The material is held down with vacuum and infinitely adjustable across the width. Energy-efficient vacuum generators ensure optimal material hold-down.

The design and build of the S3 are consistently aligned with the needs of our customers. Ergonomic design, easy handling, and user-friendly operation are the result.

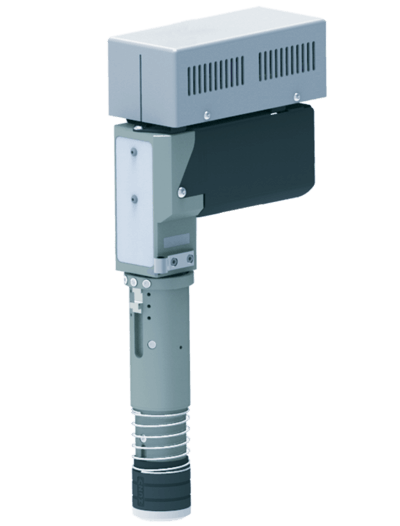

Automate picking and sorting of cut parts with a collaborative robot. This enhances the level of automation of your cutting solution and increases productivity. The collaborative robot requires no guards or protective devices.

S3 in action

Cut from the backside Board-loading extension with UNDERCAM

The Board-Loading Extension with UNDERCAM automates loading of rigid materials and ensures precise cutting with its registration system. By reducing manual work and streamlining material handling, it increases efficiency, speeds up production, and maintains high cutting accuracy.

Modular, flexible, and adaptable

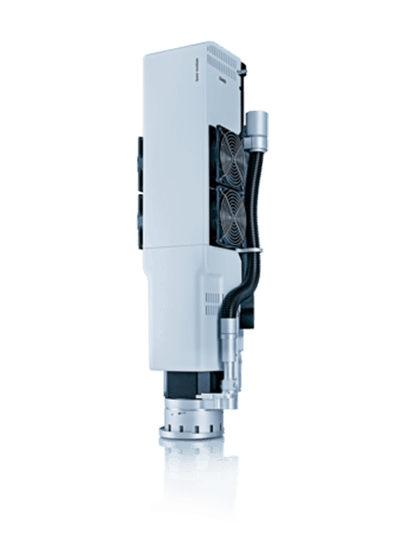

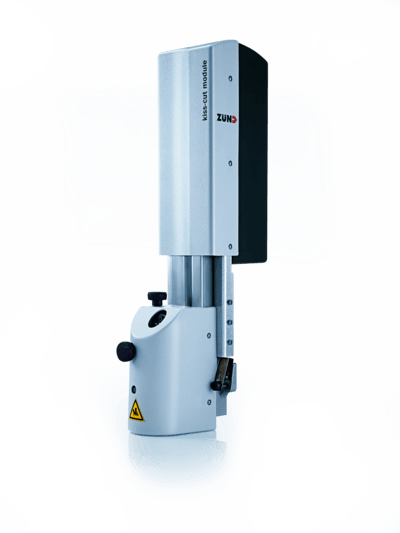

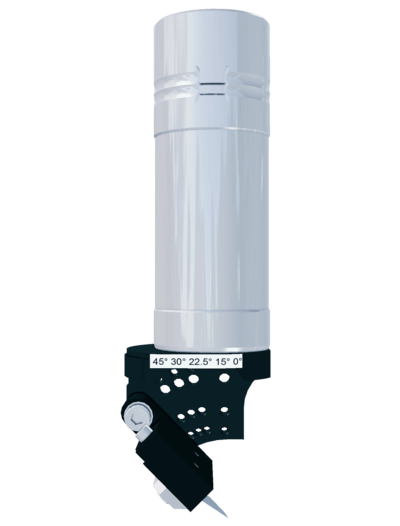

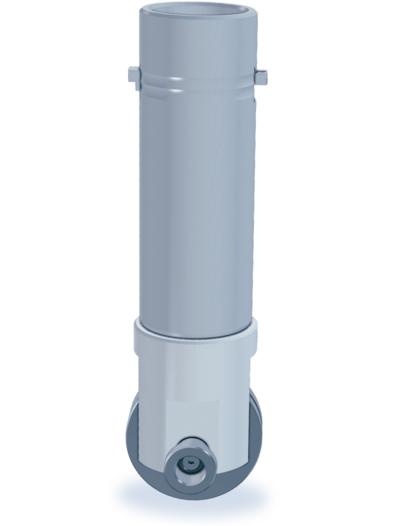

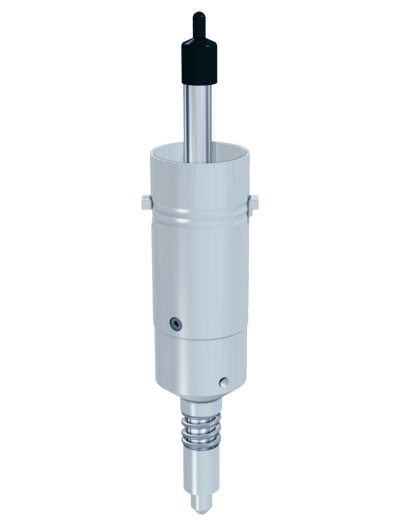

Reliable and productive – Zünd high-performance modules

Ingeniously versatile

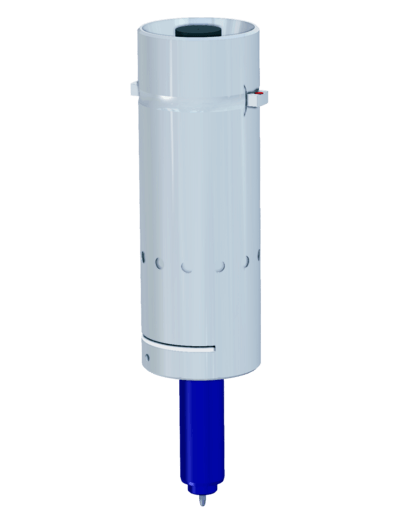

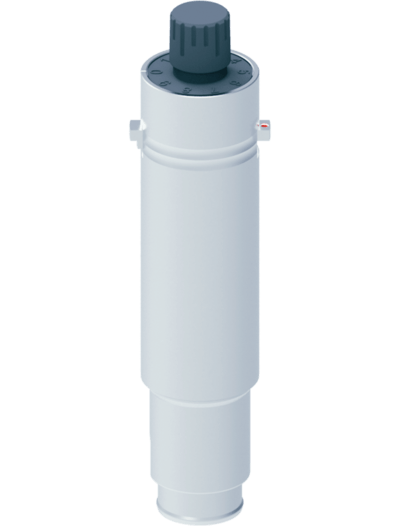

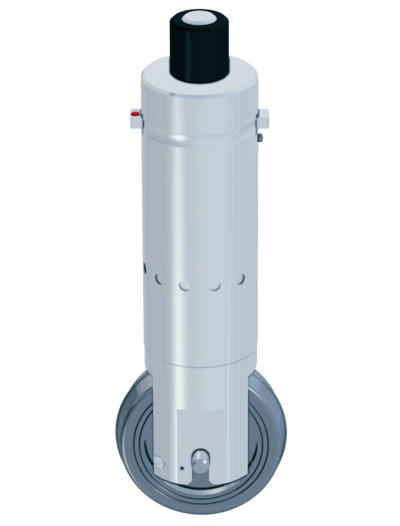

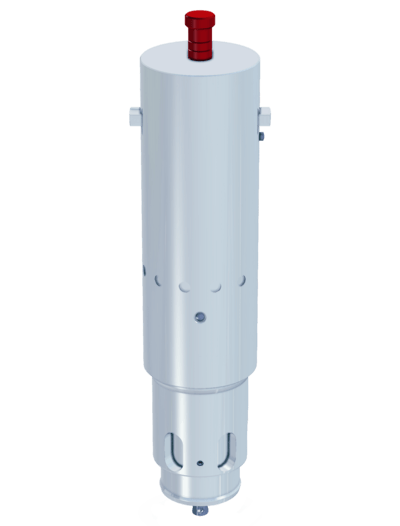

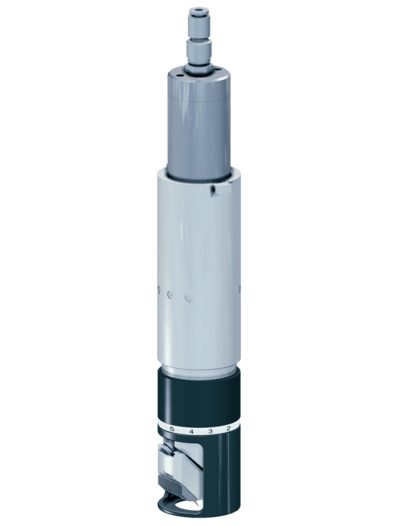

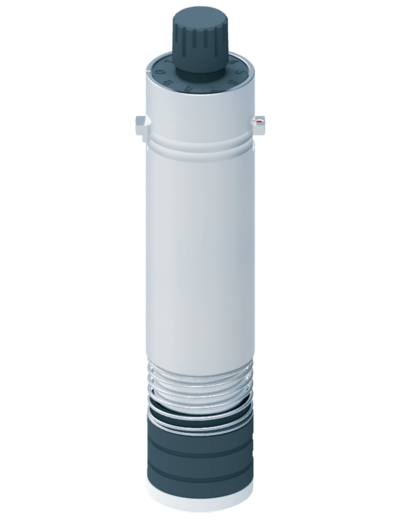

The Zünd tool concept