L3 Digital Cutter

Smart, efficient leather cutting

Perfect for the leather industry

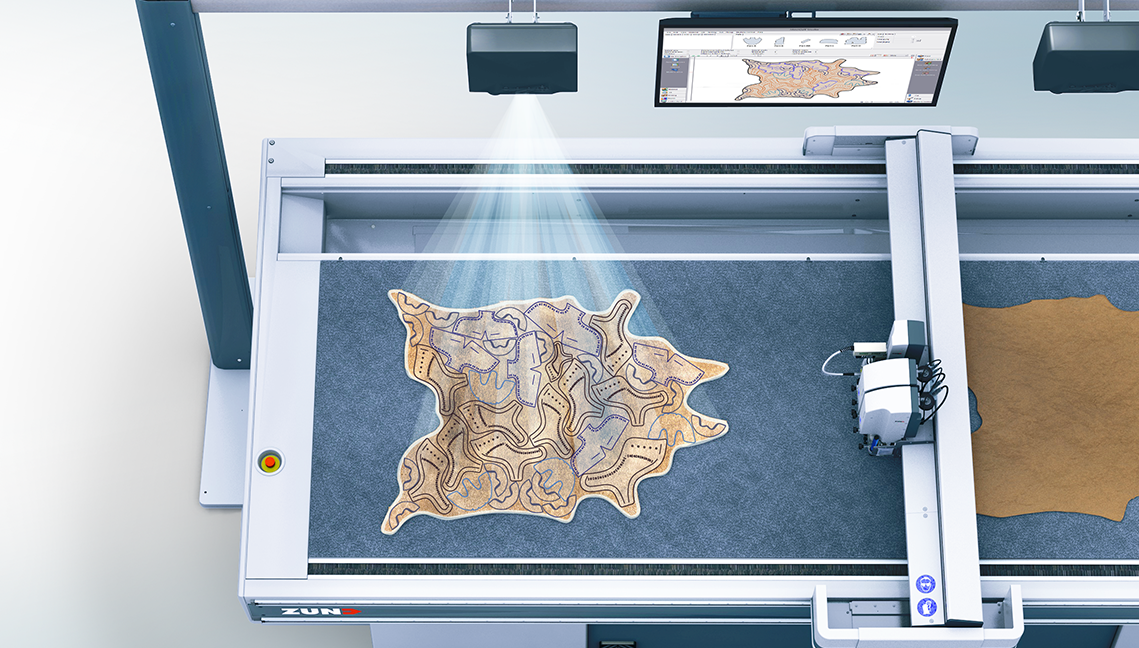

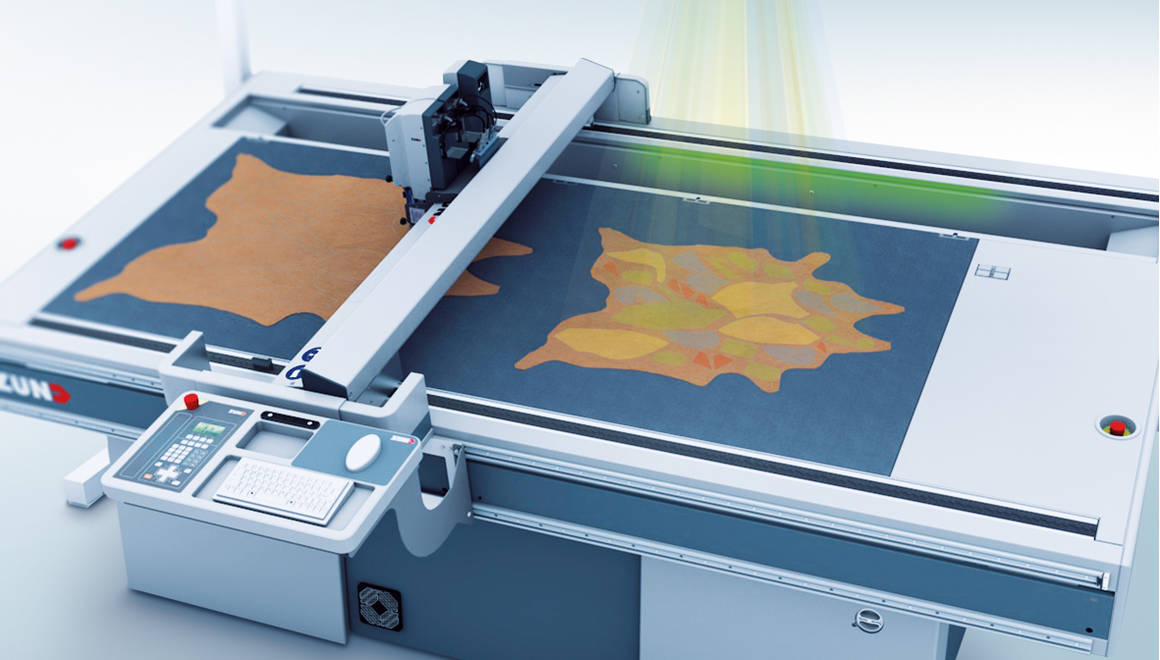

Projection systems

Projection systems support the operator throughout the process – from capturing the leather to nesting and removing the cut parts.

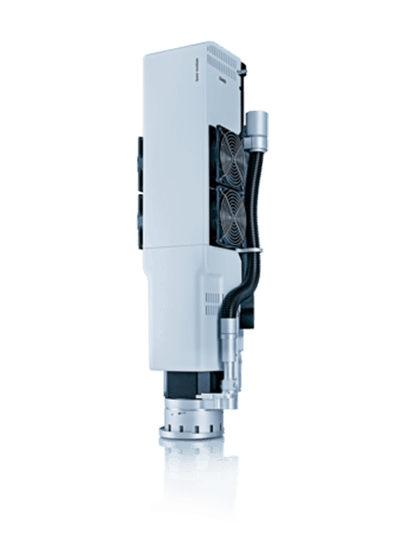

Optimal material hold-down

Energy-efficient vacuum turbines ensure reliable material hold-down during the cutting process. The vacuum area is divided into zones, which can be switched on and off individually across the width of the machine.

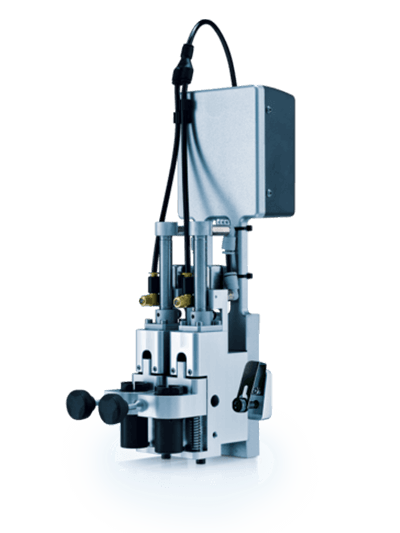

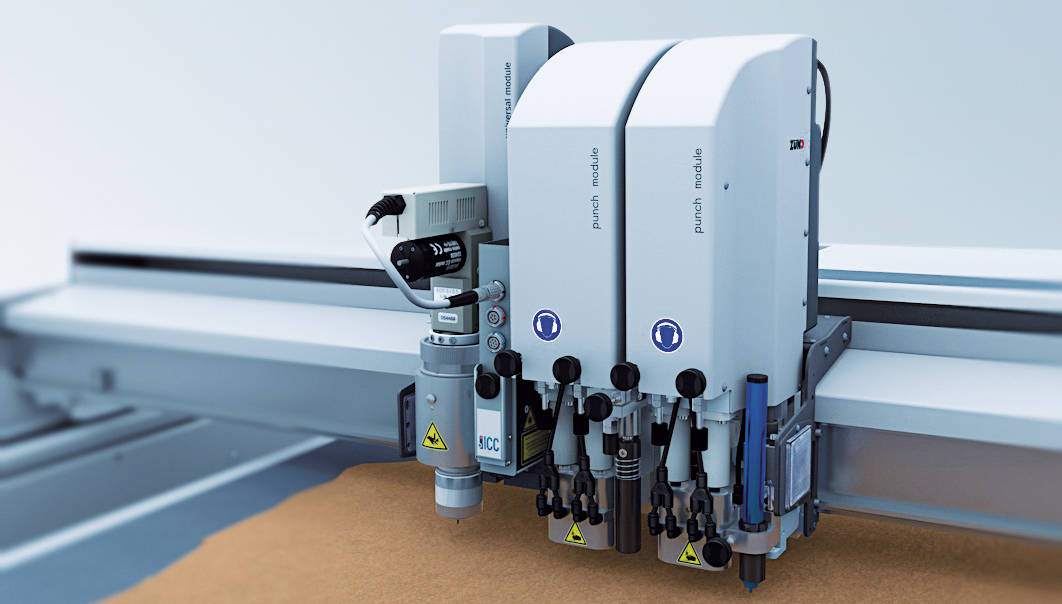

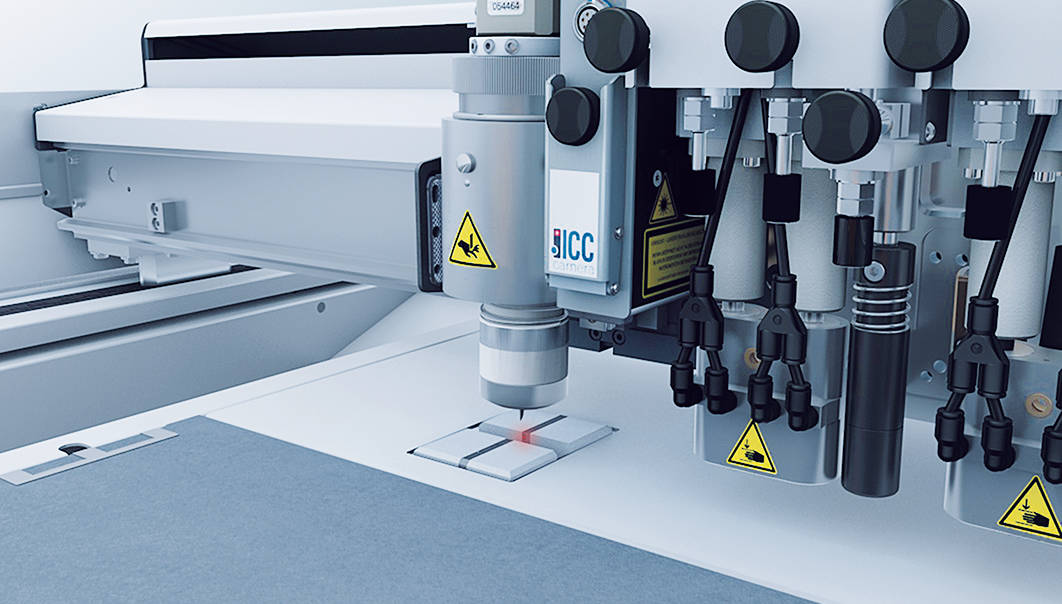

A flexible choice of tools

You have the flexibility to choose precisely the tools you need for the job at hand. Combine the required tools based on your specific requirements. You can equip the L3 with up to seven different tools.

Cutting non-stop

Loading/unloading and cutting can all take place at the same time. A green LED strip clearly indicates at any time which area is safe to access.

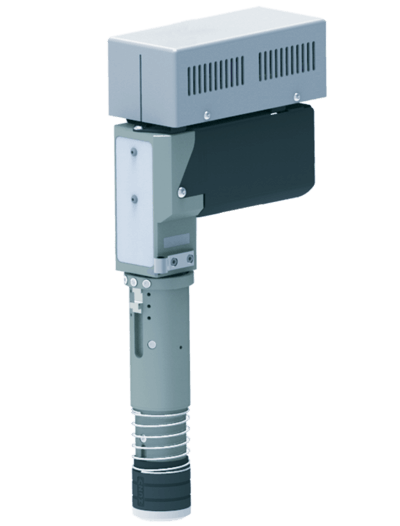

Integrated Tool initialization

The setup of cutting, tools occurs fully automatically. The ITI Initialization System makes the process quick and precise.

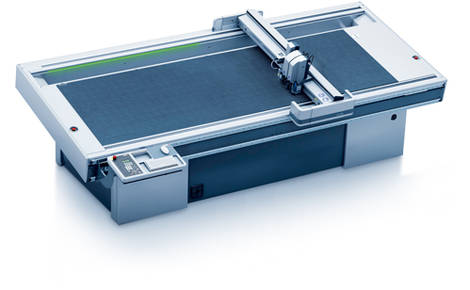

Ergonomic operation

The L3 working surface is slanted, which facilitates the loading/unloading process. For optimal accessibility, the control panel is mounted on a guide rail and can be freely moved.

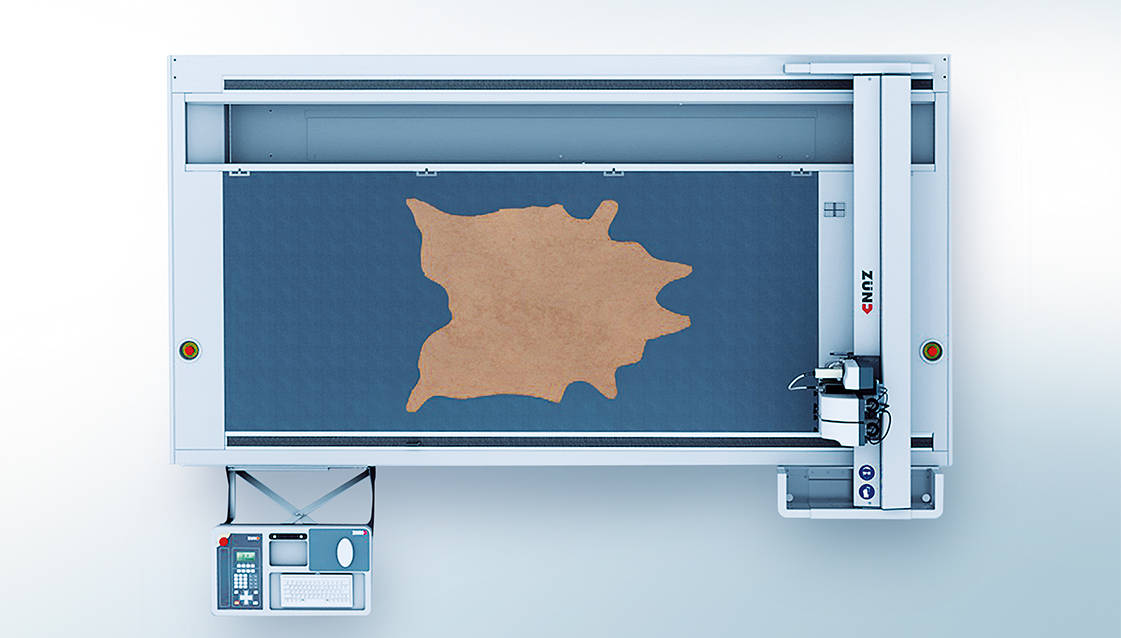

L3 overview

Process leather, sole, lining, and stencil materials precisely and efficiently with the L3 cutting system. With the right tool, you can cut leather at a speed of up to one meter/40 in per second. With an L3 you can produce leather goods economically, efficiently, and of premium quality.

Couches and sectionals, office chairs, car seats, leather steering wheels – Zünd cutting technology is at the origin of so many products we encounter on a daily basis. Many well-known manufacturers in the leather industry rely on Zünd cutting systems. This is not surprising considering the outstanding performance, low cost of ownership, and easy integration into your workflow ensuring a rapid ROI.

Zünd cutting systems are used both in prototyping and production. We can offer you the right solution for your production environment, tailored to your individual needs. With 17 cutter sizes, a large variety of tools, and a range of sophisticated material-handling solutions, we can guarantee a perfect fit.

The L3 cutter is designed for non-stop operation with loading/unloading and cutting all taking place at the same time. A green LED strip indicates in which area production has ended and new material can be loaded.

The Zünd L3 cutter in action

Flexible in the choice of materials

Leather uppers

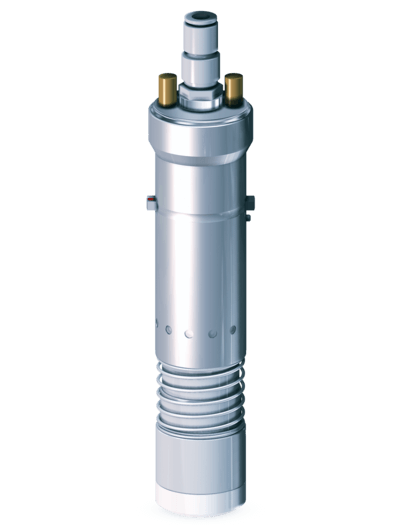

Cutting and perforating tools specially developed for leather cutting ensure optimal performance and productivity.

Sole materials

Hard, tough materials require particularly powerful cutting tools. Robust tools such as the Electric Oscillating Tool – EOT or the Pneumatic Oscillating Tool – POT are perfectly suited for cutting sole materials.

Stencil materials

Process stencil material of any kind. For materials that are too hard or dense for cutting, Zünd offers a range of routing tools to get the job done.

Roll materials

Leather processing is your core business and you want to increase the flexibility of the L3 even more? With the optional roll-off unit, you can easily and efficiently process rolls up to 2 m wide and a weight of 70 kg.

L3 Digital Cutter Sizes

C-40

width (mm)

1000

Length L3 (mm)

2300

C-56

width (mm)

1000

Length L3 (mm)

3240

Modular, flexible, and adaptable

Reliable and productive – Zünd high-performance modules

Ingeniously versatile

The Zünd tool concept