Set yourself free!

Eye in the Sky innovates the cutting process – and provides a remarkable impact on production throughput

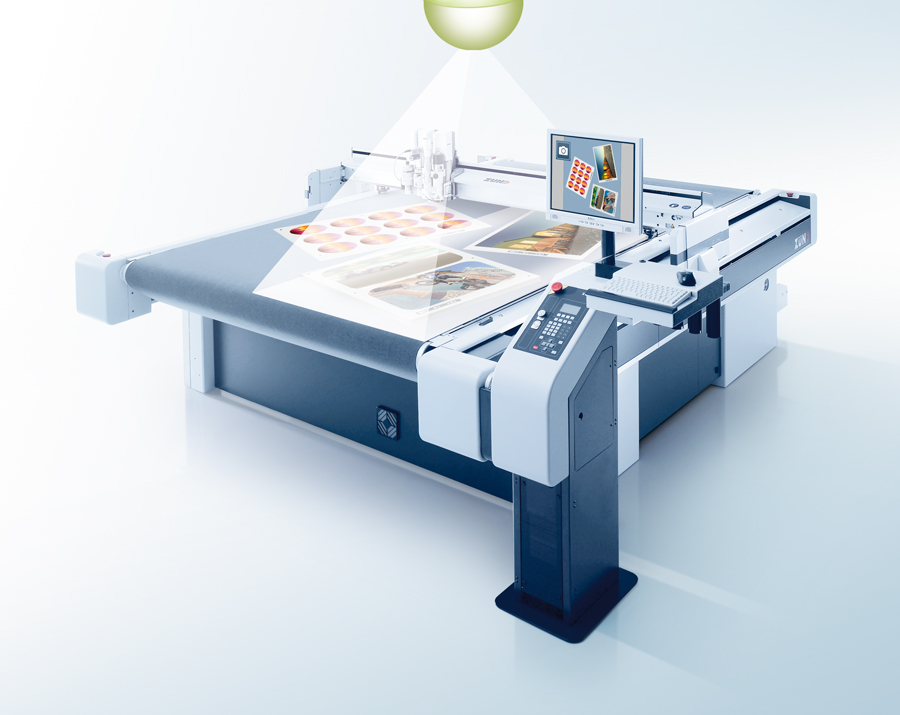

Eye in the Sky

With just one click EIS automatically identifies and starts processing all jobs placed on the cutter. You can even place different jobs on different materials on the cutter and proces them at the same time.

Place multiple jobs on the cutter – no need to open or batch different files together. EIS will detect unique fiducials, printed on each job, to identify material, cutting parameters and positioning on the cutter.

This simplified interaction will save time and allow the operator to do other things during the cutting process.

Advantages:

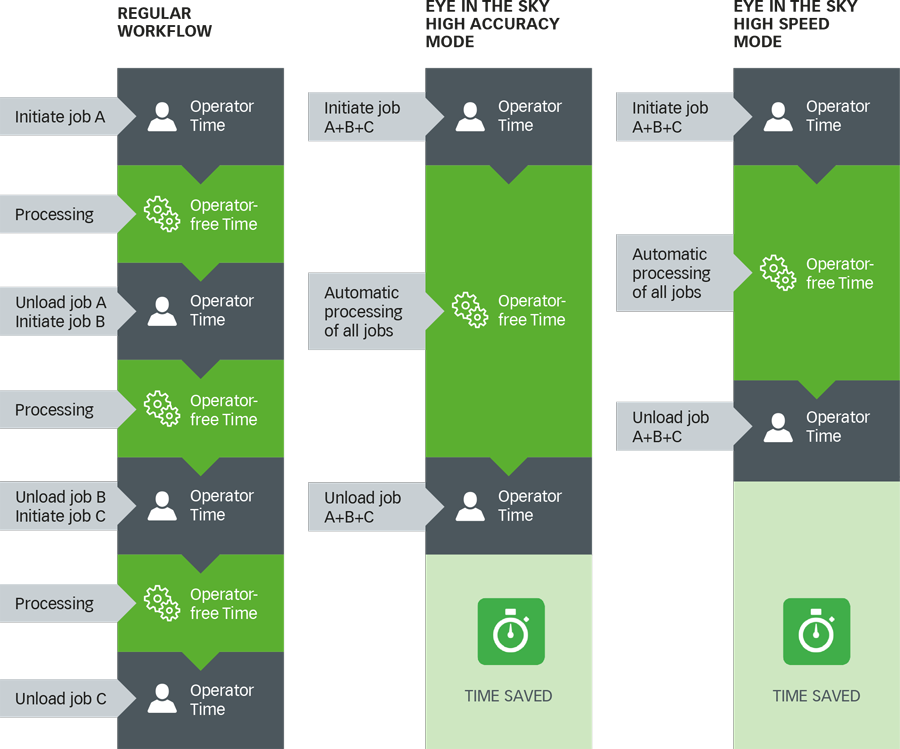

Productivity do not only depend on processing speed. Factors like job shift including material handling and file loading, have a remarkable impact on production throughput. With EIS the machine automatically identifies jobs and starts cutting – allowing the machine to process unattended for longer periods of time.

Full flexibility with different production modes

Keep the cutter going whether cutting rigid boards or flexible materials from roll. Different production modes can be selected for single-zone, double-zone and continuous production.

In single-zone production the operator can fill up the cutting area with different jobs on different substrates, click and leave. Ideal when working with small sheets as you really benefit from filling up the cutting area allowing the machine to operate unattended for longer periods.

In double-zone production the system runs in tandem mode. The operator can fill up one end of the machine as it is cutting in the other end and vice versa. In this way the machine is constantly working. Jobs and substrates can be mixed for maximum flexibility.

In continuous production mode a conveyor system on the machine automatically advances the next job when the previous job is finished – whether coming from roll or loaded as sheets.

EIS is also compatible with automation systems such as sheet feeders, robots, etc.

One-shot camera registration for high speed operation

Let EIS detect the register marks and reduce time for camera registration. EIS can detect both fiducials and register marks in one single shot so job identification and job positioning are detected in seconds, and the cutting starts.

For jobs requiring maximum precision EIS can be used for detecting fiducials only while the ICC camera detects the register marks.