Cut-it! Advanced Cutting Software

Easier and more efficient than ever before!

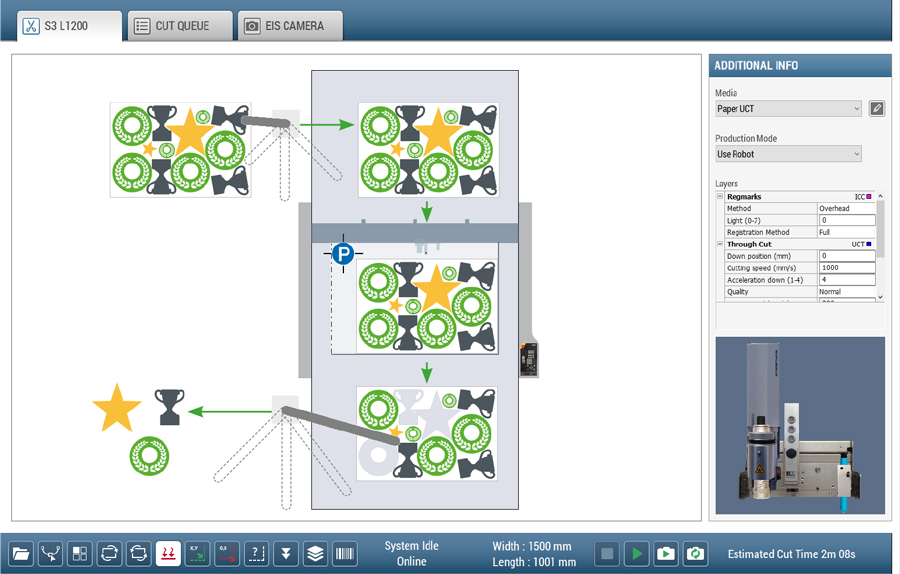

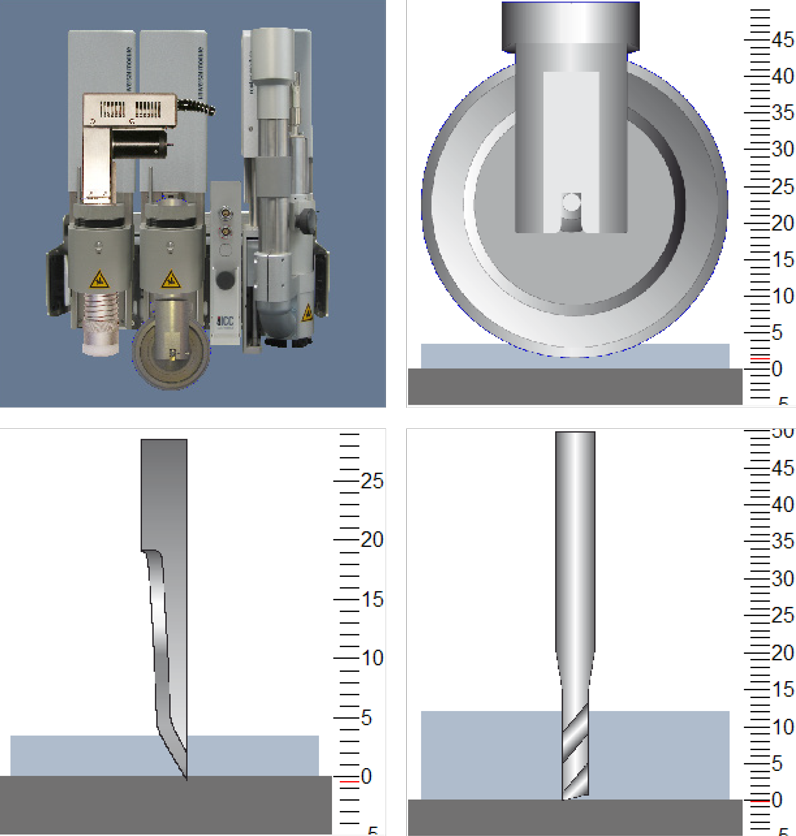

Cut-it controls Zünd cutters through a very user-friendly interface. Optimal production capacity is reached through interactive and graphic “what you see is what you get” features where all parameters can be altered dynamically on-the-fly without having to stop and restart. Cut files are displayed in dimensions related to the actual machine size and images on screen shows the active tools on the cutter. A “tool bar” at the bottom of the screen and “function keys” on the PC keyboard are easily setup and customized to short-cut functions.

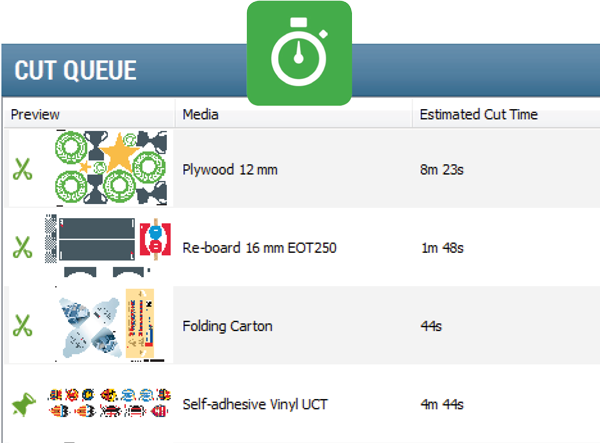

Cut Queue

Get easy overview of incoming jobs, organize and keep track on produktion

Great overview of incoming jobs in the Cut Queue

In the Cut Queue you see all incoming jobs. Colored icons illustrate if jobs are ready for cutting or if an operator action is needed. An estimated cut time, based on the actual media settings, is displayed for each job. By selecting multiple jobs, you get a quick overview of the total production time.

All jobs can be sorted or filtered by material type, customer name, submit date, due date, cut order, etc. for best overview.

The Cut Queue also allows combining multiple jobs for batch processing.

Old jobs are kept in a History queue for a certain time for easy access and re-production. In the history queue you also see the actual production time for each job.

Compatible with any CAD program

Cut-it imports vector files from all leading CAD programs including .DXF, .PDF, .AI, .CF2, .ACM, .SAM, etc. Import settings can be customized for automatically matching specific layer names to different tool actions.

.

Simply scan the barcode and Cut

Cut-it is compatible with leading RIPs and workflow systems, and can be setup for reading printed barcodes, with a barcode scanner, for easy job identification.

Media Library

Think productivity, and leave the material knowledge to Cut-it!

MEDIA LIBRARY

Cut-it includes a large media library with predefined parameters for commonly used materials. Don’t worry about cutting speed, acceleration, creasing power, v-cut depth, routing RPM, etc. Simply open the cut file and select media – all cut parameters are preset according to the individual tool selection.

Additional medias can easily be imported, created or customized by yourself whenever needed.

Job parameters can be saved temporarily to the specific job or generally to the media for all new jobs.

For graphic applications, in combination with Prepare-it, the medias further include a complete set of “prepress” settings for register marks, barcodes, nesting etc.

Cut-it users can customize the media library by displaying, creating, duplicating and downloading just those medias that are relevant for them.

A dedicated leap!

Enjoy easy and accurate editing – the short cut to productivity and a fluent workflow!

EDITOR

DEDICATED TOOLS MAKE CUTTING EASY AND ACCURATE

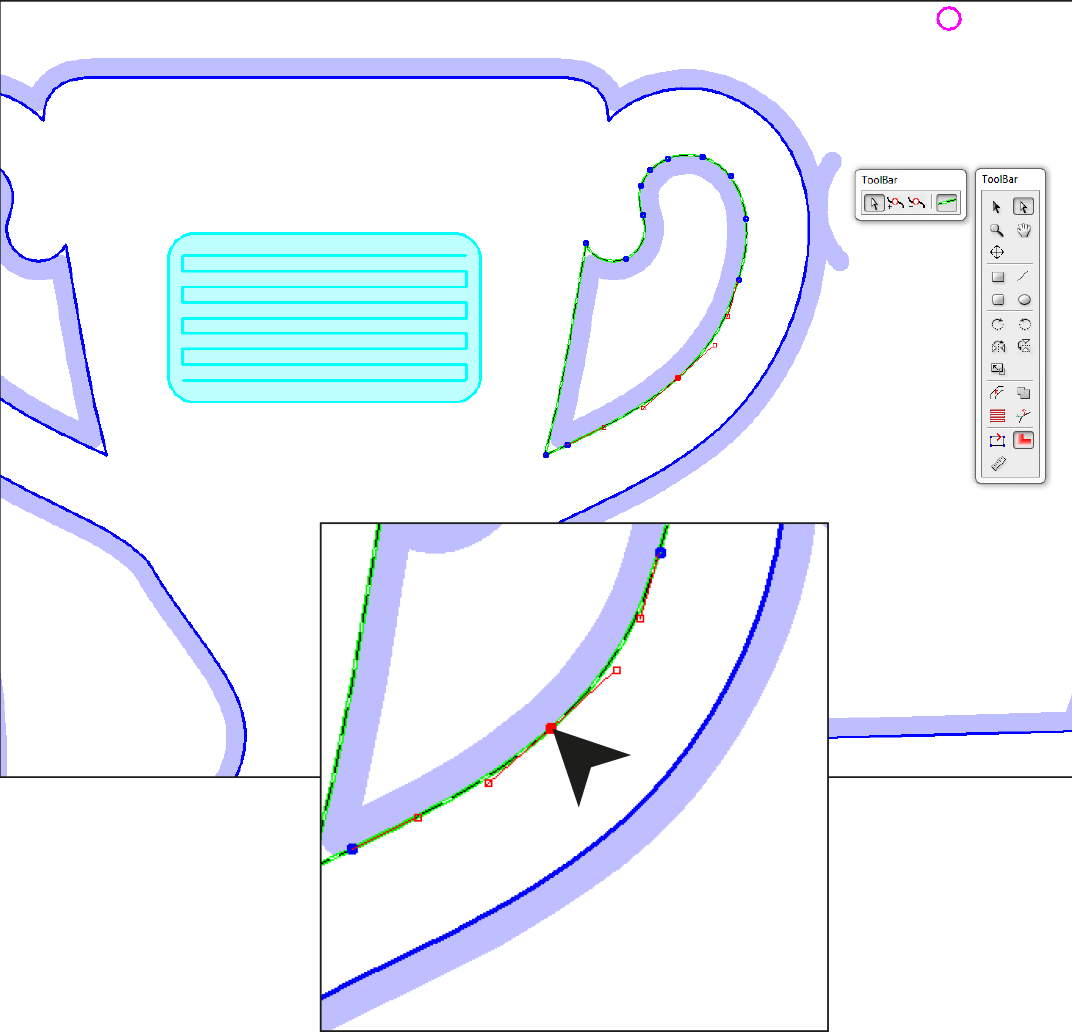

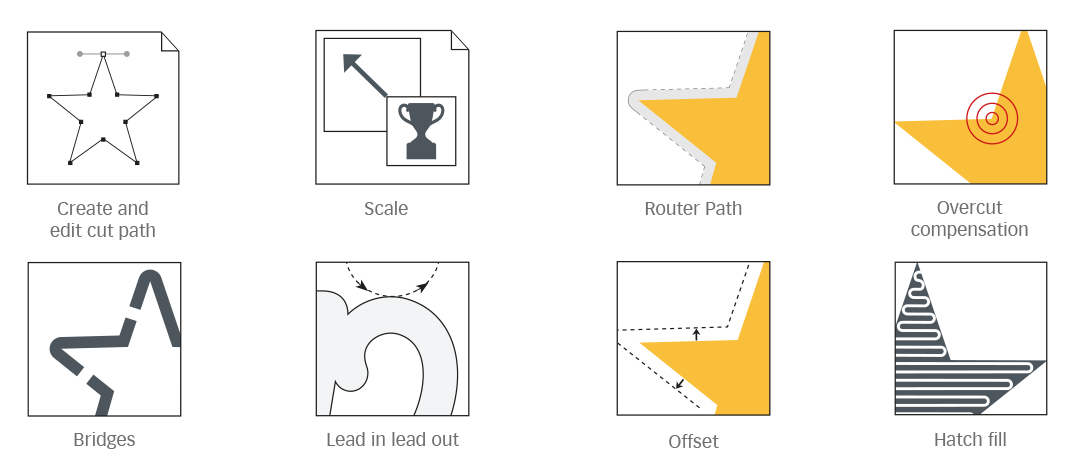

Cut-it includes numerous dedicated features to improve cutting and thereby the end product. A user-friendly Adobe like editor allows the operator to make last-minute changes of the cut paths – including editing curve points, moving start points, job scaling, creating offset, creating new curves, etc.

More advanced features for routing and cutting can be applied when needed.

Gain Perfect Control!

Cut-it makes it easy to work smarter with intelligent functionalities!

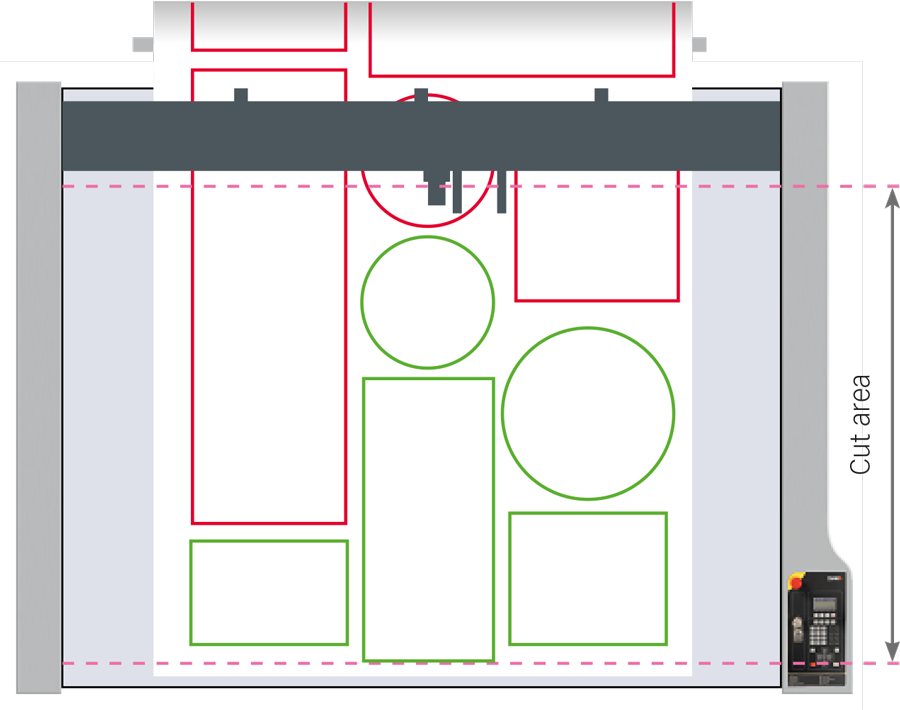

Smart feed

Smart Feed can be activated to ensure optimal cut quality on roll jobs. By allowing feeding in smaller steps all parts smaller than the cut area will be cut in one continuous cut. Only parts longer than the cutter will be split and cut in multiple sequences.

High precision cutter with cameraguided registration!

Using the ICC camera detect register marks, the vision module ensures perfect cut-to-print accuracy. Based on the detection, the system automatically positions and rotates the cut information according to the printed material positioned on the cutter.

Perfect fit for distorted jobs

Different compensation modes can be selected depending if the cut must be scaled, skewed or shrunk according to the print or if it must be cut 1:1 with best possible positioning.

Perfect fit for jobs longer than the cutter

When cutting large printed banners longer than the cutter the Vision module ensures perfect alignment for the end- and start points of the cutline.

Perfect fit for backside cutting

Different registration methods are available for accurate cutting of printed sheets from the backside.

Edge detection and reading cutouts are both possible with the ICC Camera.

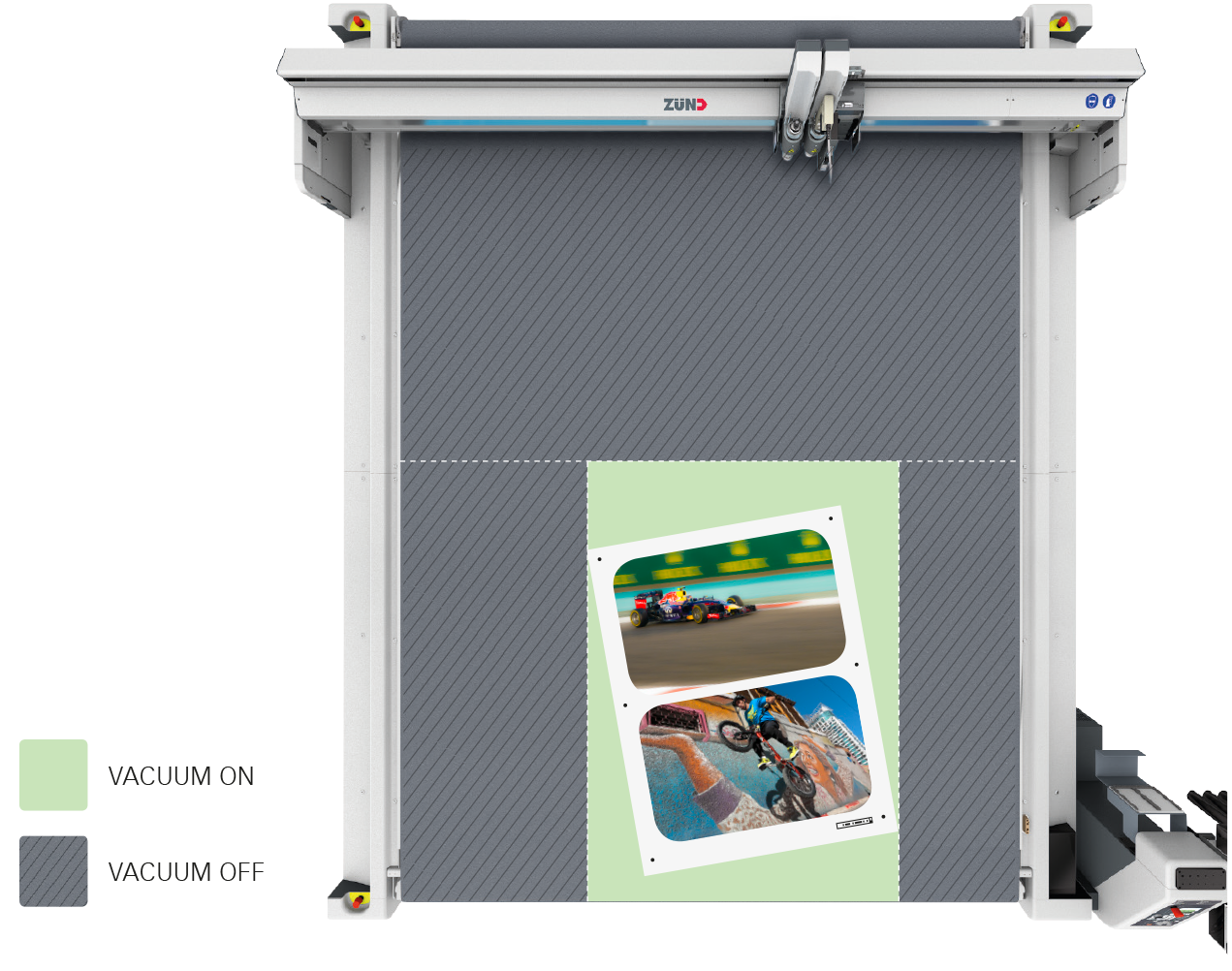

Intelligent vacuum hold-down

Cut-it automatically adjusts the vacuum area on the Zünd cutter according to the job being processed.

Depending on the cutter configuration, the vacuum width can be controlled from left and right side as well as front and rear. Also, the vacuum level can be automatically controlled based on media type.

Set yourself free!

Eye in the Sky innovates the cutting process – and provides a remarkable impact on production throughput

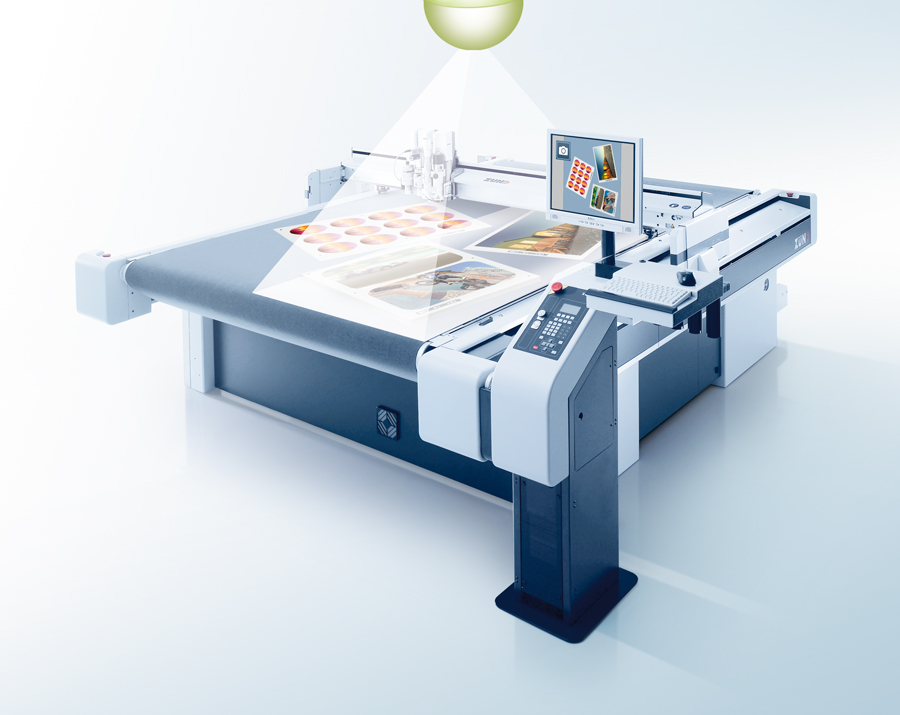

Eye in the Sky

With just one click EIS automatically identifies and starts processing all jobs placed on the cutter. You can even place different jobs on different materials on the cutter and proces them at the same time.

Place multiple jobs on the cutter – no need to open or batch different files together. EIS will detect unique fiducials, printed on each job, to identify material, cutting parameters and positioning on the cutter.

This simplified interaction will save time and allow the operator to do other things during the cutting process.

Advantages:

• Highest flexibility

• Save time

• Maximize cutter capacity

• Cut different jobs together

• Mix substrates

• Automate cutting

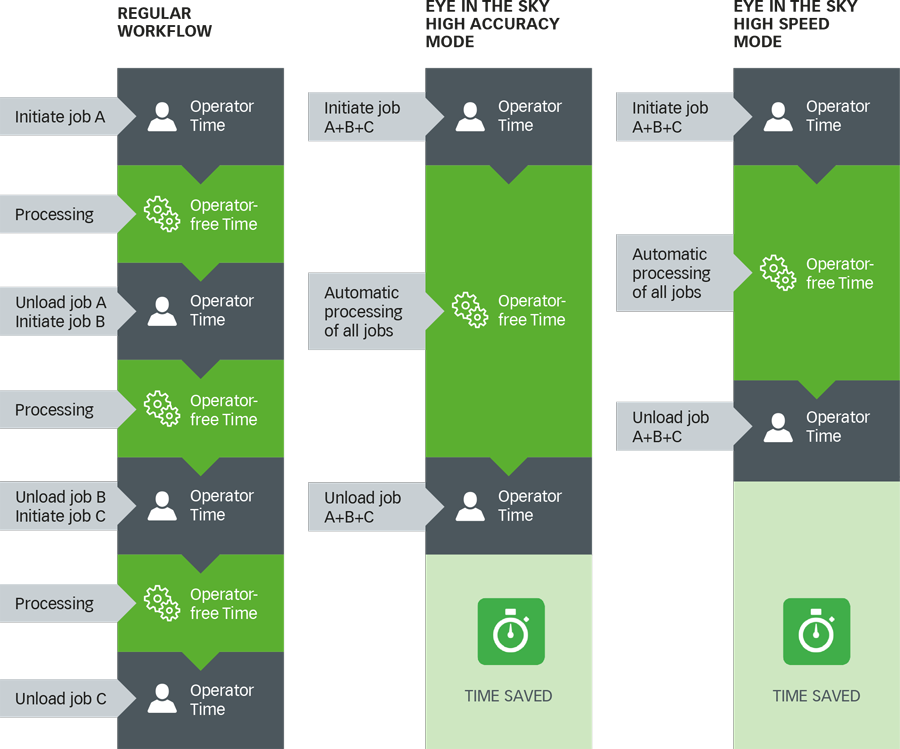

Productivity do not only depend on processing speed. Factors like job shift including material handling and file loading, have a remarkable impact on production throughput. With EIS the machine automatically identifies jobs and starts cutting – allowing the machine to process unattended for longer periods of time.

Full flexibility with different production modes

Keep the cutter going whether cutting rigid boards or flexible materials from roll. Different production modes can be selected for single-zone, double-zone and continuous production.

In single-zone production the operator can fill up the cutting area with different jobs on different substrates, click and leave. Ideal when working with small sheets as you really benefit from filling up the cutting area allowing the machine to operate unattended for longer periods.

In double-zone production the system runs in tandem mode. The operator can fill up one end of the machine as it is cutting in the other end and vice versa. In this way the machine is constantly working. Jobs and substrates can be mixed for maximum flexibility.

In continuous production mode a conveyor system on the machine automatically advances the next job when the previous job is finished – whether coming from roll or loaded as sheets.

EIS is also compatible with automation systems such as sheet feeders, robots, etc.

One-shot camera registration for high speed operation

Let EIS detect the register marks and reduce time for camera registration. EIS can detect both fiducials and register marks in one single shot so job identification and job positioning are detected in seconds, and the cutting starts.

For jobs requiring maximum precision EIS can be used for detecting fiducials only while the ICC camera detects the register marks.

Cooperate with succes!

Automate with robots – and push the limits of your production even further!

Robot interface

Use Cut-it for connecting robots to the Zünd cutter for loading and unloading. Different setups can be defined depending on type of robot and gripper. Cut-it works with large industrial robots and small collaborative robots with vacuum plate for picking whole sheets or suction cups for picking individual parts.

.

No manual setup

The Cut-it robot module includes dynamic unloading. No setup for the individual jobs is required. Cut-it automatically defines the pick position of each part and sends it to the robot.

Based on the size and shape of the parts, Cut-it also decides the number of suction cups to be used for picking the parts. Multiple parts can also be unloaded together, when using grippers with multiple suction cups.