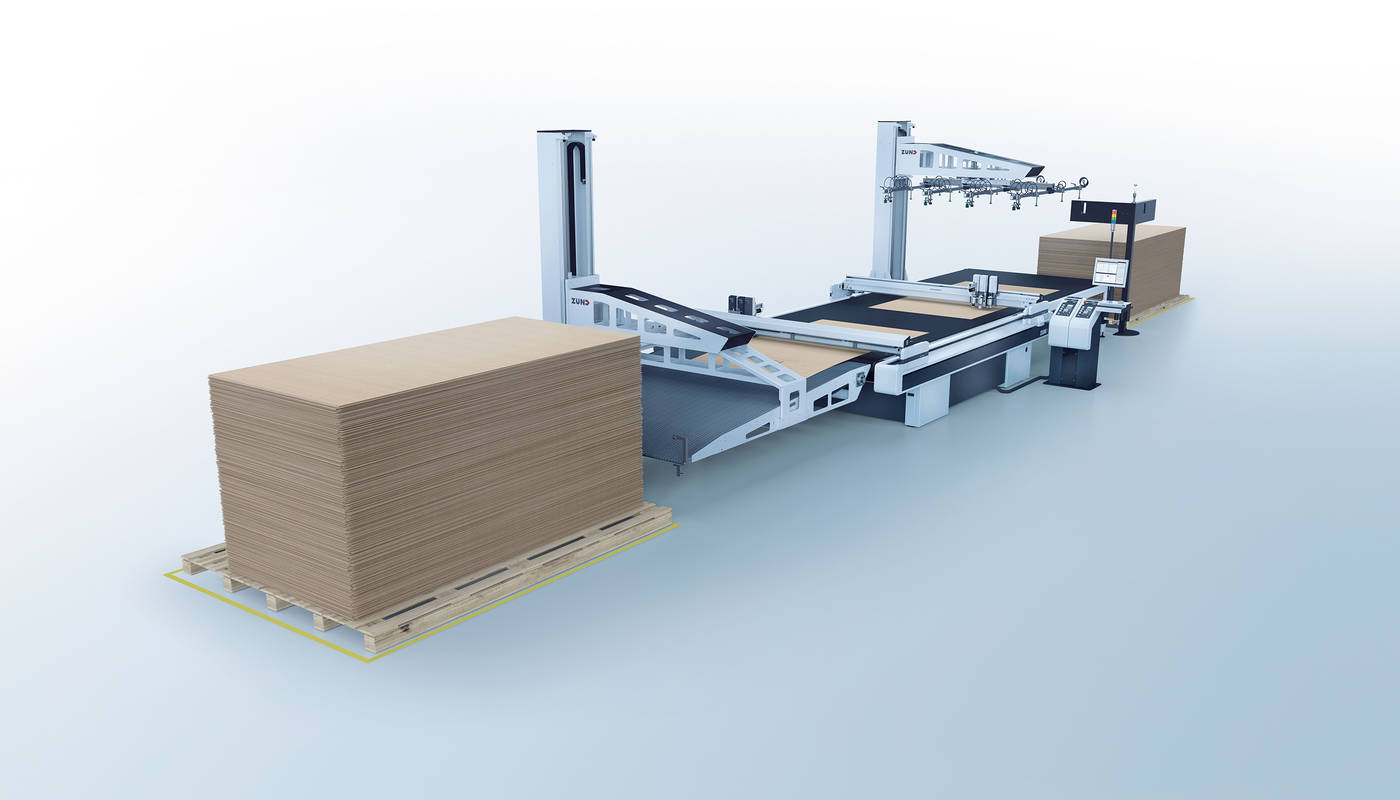

Board Handling System – BHS150

Industrial Cutting

Digital cutting at an industrial level

The unique combination of fully automatic material handling and high-performance digital cutting is the key to industrial-level production. The BHS150 extends operating time while decreasing operating costs.

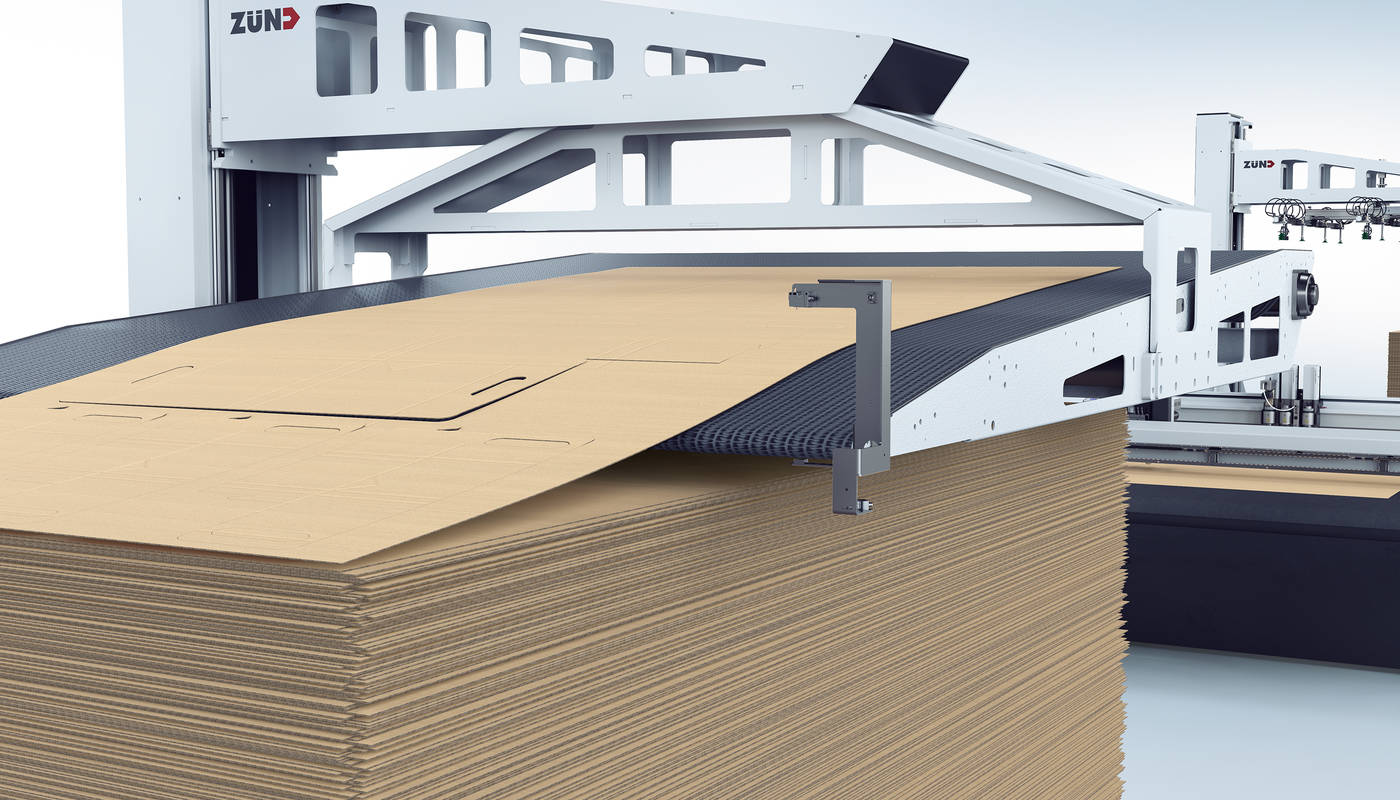

Efficient stacking with the BHS150

The 1.5 m/5 ft stack height allows for significantly longer uninterrupted operating time. As a result, even long runs can be finished efficiently and economically. Finished stacks can be removed without interrupting production.

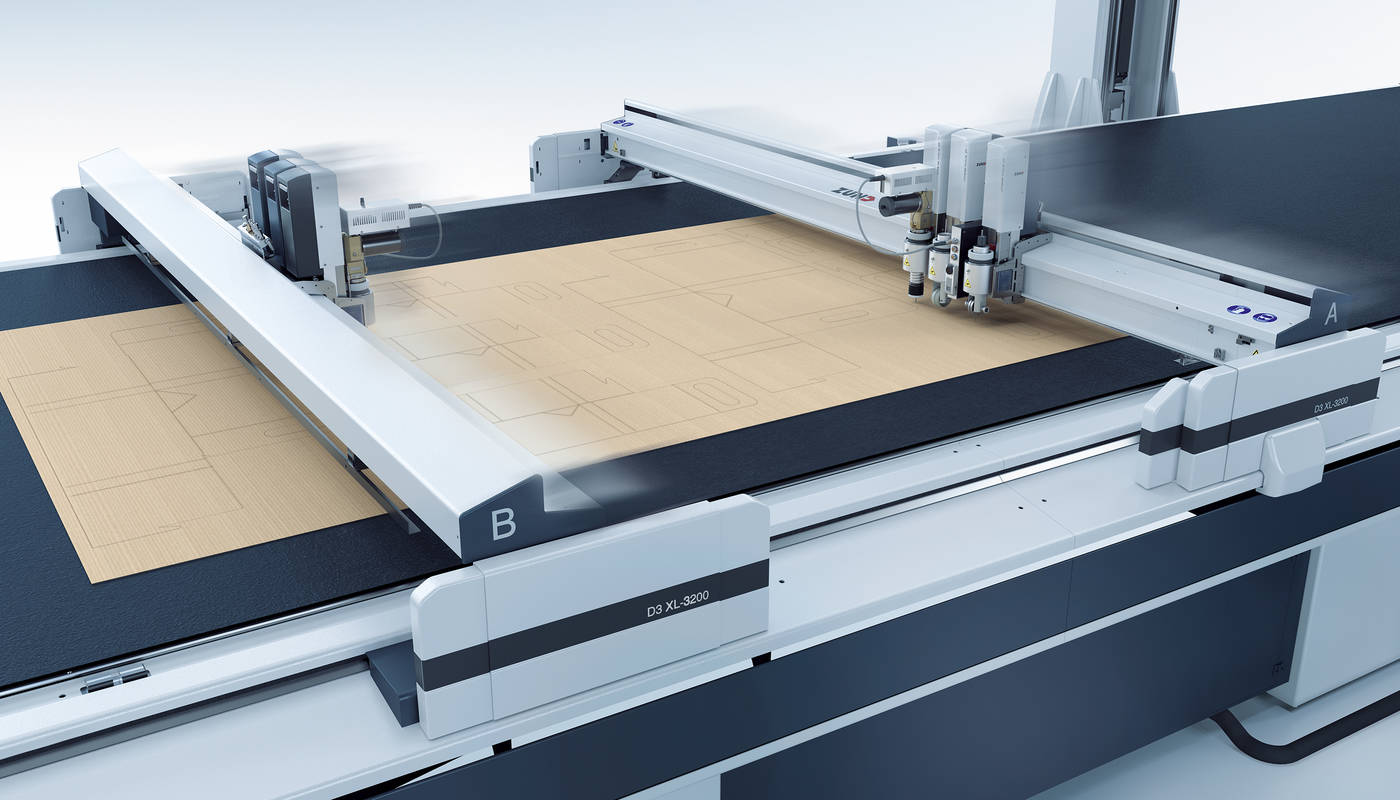

Top production speed to meet the highest demands

The BHS150 is designed for operation with Zünd G3 and D3 series cutters. With its dual-beam technology, the D3 provides a significant increase in performance and thus offers maximum productivity.

Capture job data automatically

During the loading process, a scanner captures job information via printed QR codes. This enables reliably identifying different jobs within a stack for fully automated processing.

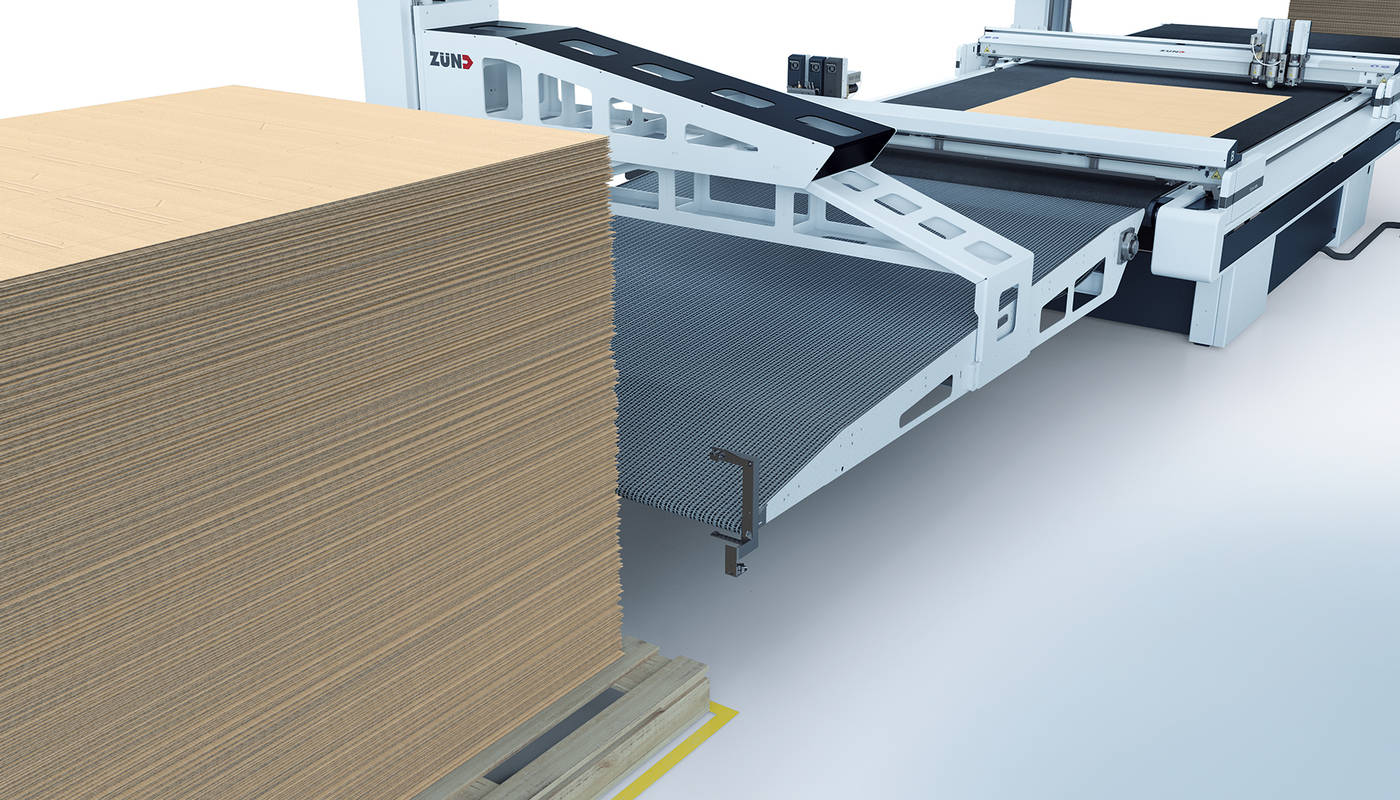

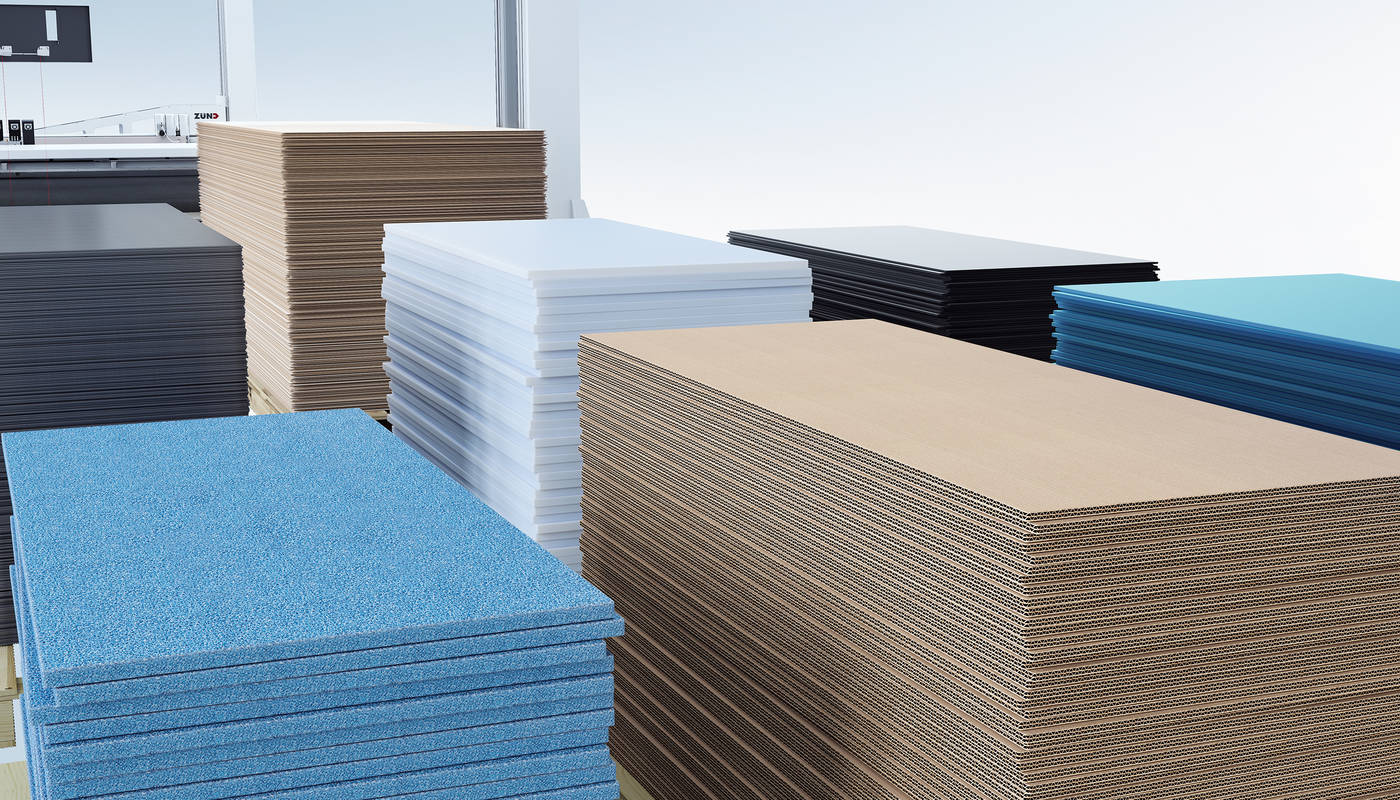

Ideal for different material thicknesses

The BHS150 can efficiently process materials up to 110 mm/4.3 in thick.

Bridge-free stacking

The off-load conveyor and stacking system deposits cut sheets in a perfect stack on a pallet. Depending on the job, this stacking method eliminates the need for bridges to hold cut parts in place. This facilitates separating cut parts from waste, saving both time and money.

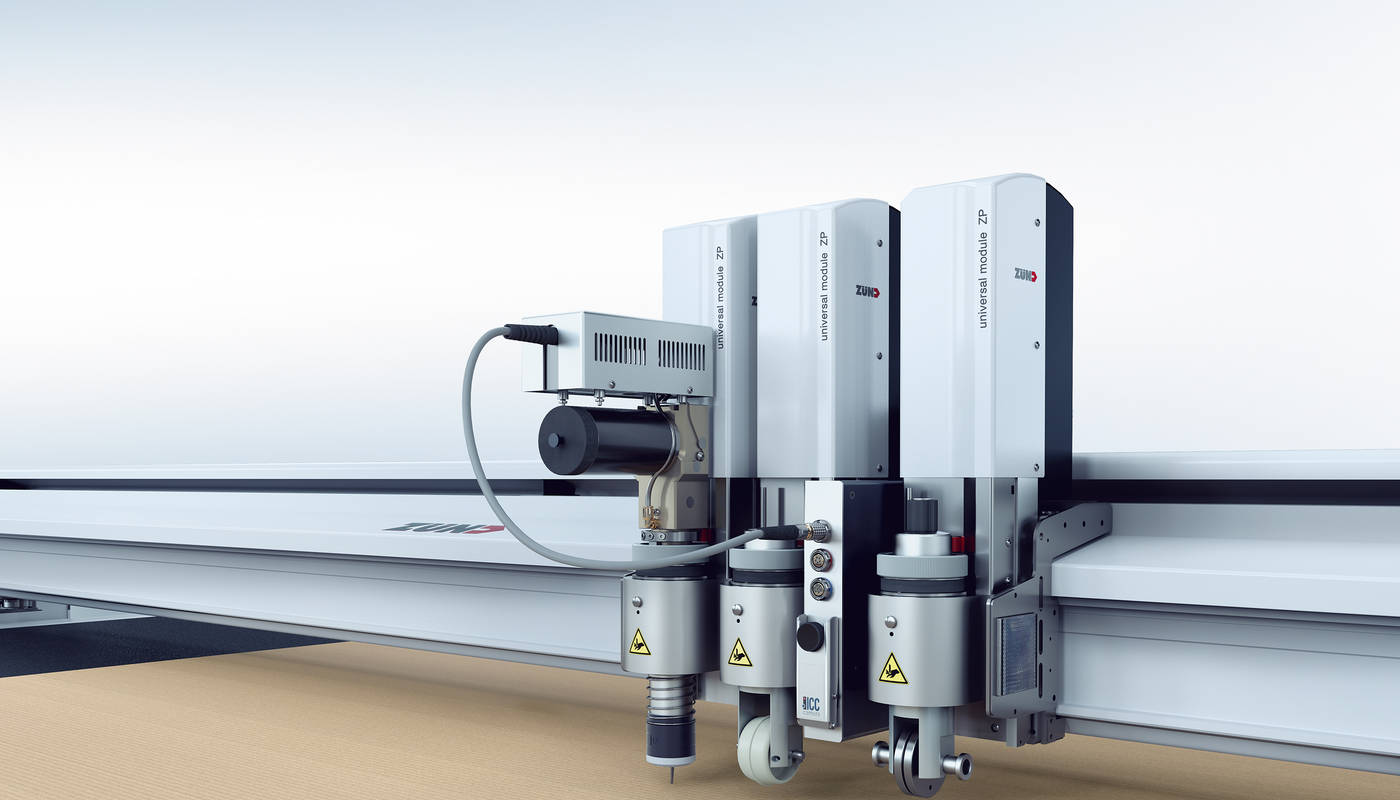

Modular solutions

Cutting, creasing, perforating – Zünd’s modular concept allows users to freely select processing methods. Up to three different methods can be used for any given job, without having to interrupt the ongoing production for tool changes.

Economical even with smaller formats

The loading unit can feed multiple sheets at once. Even smaller sheet or board sizes can be processed efficiently by making full use of the working area.