Published by Sign & Print SE, April 2024

Text and photo: Felix Alnemark

Recently, Graphic Profile relocated to a larger facility and made significant investments in two Zünd cutters and a flatbed printer. This expansion has substantially increased their operational capacity, enabling them to compete with larger firms for projects.

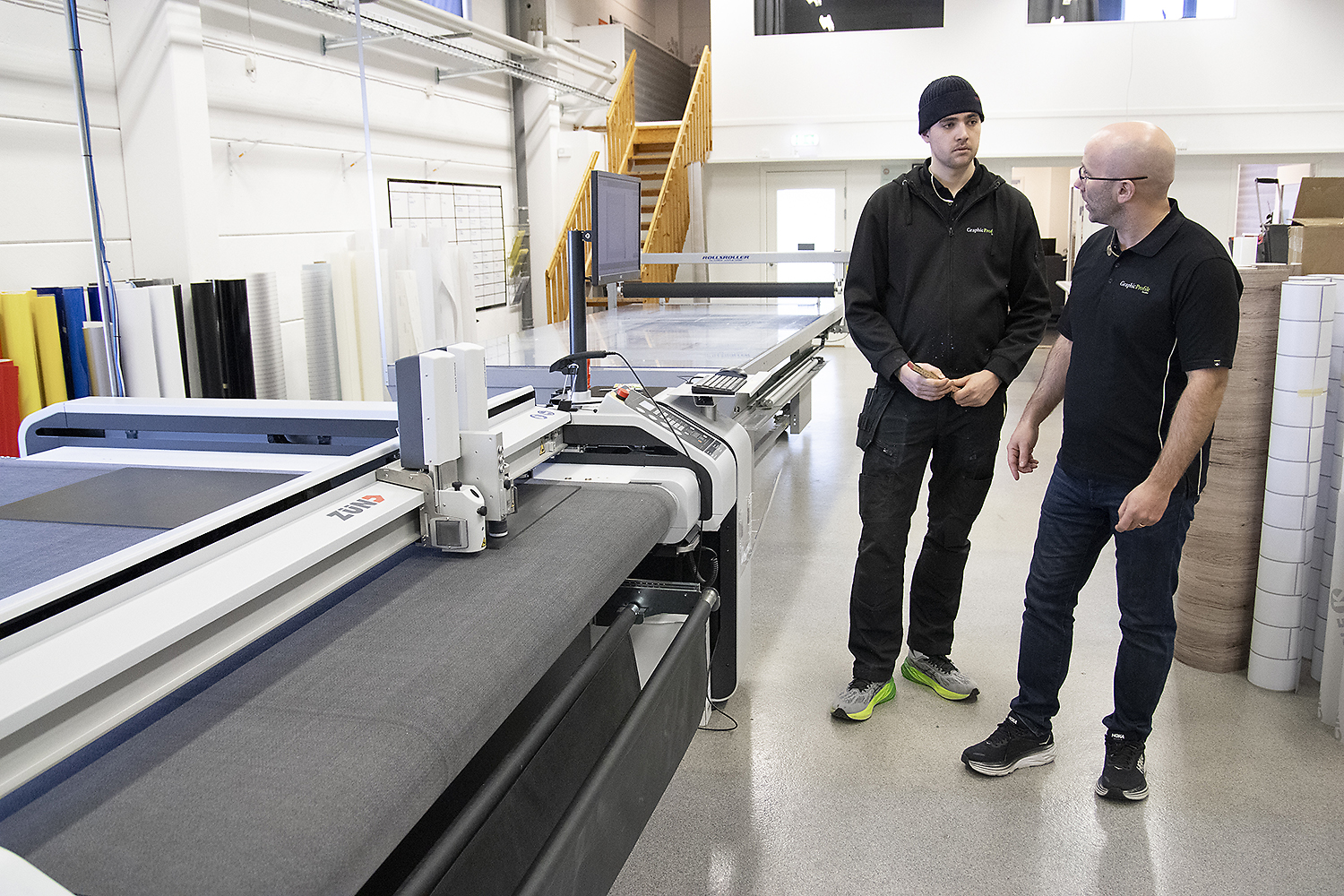

According to Tom Jacobsson, CEO and co-owner, “The Zünd cutters are the heart of our operations, as everything goes through them.”

The company specializes in in-store materials and campaigns, foiling, and various products such as large formats, signs, banners, stickers, decorations, and printed materials.

Customer demand has also influenced the company’s purchasing decisions. “Unexpectedly, we received a project that required routing capabilities,” adds Tom Jacobsson.

They already have Zünd’s G3 XL-3200, a 2.3 × 3.2 meter digital cutter equipped with a heavy-duty router module for the toughest materials.

The cutter features advanced automation, including the “Eye in the Sky” solution—a camera system that monitors the workflow and automatically reads register marks to ensure accurate dimensions and formats in cutting jobs.

Additionally, the machine incorporates an integrated tool selection system, enabling operators to save time and eliminate the need for repeated calibration.

Recently, they’ve also invested in a smaller Zünd cutter, the S3 L-1600. Despite its compact size of 1.8 × 1.6 meters, this digital cutter operates swiftly.

“Anything that doesn’t require routing, we can process on this cutter,” Tom Jacobsson remarks.

The G3 XL-3200 is the larger of the two Zünd tables, measuring 2.3 × 3.2 meters. It is equipped with a heavy-duty router module designed to handle the toughest materials.

“The Zünd cutters are easy to deal with. They’re not that complicated. I think they work very well,” says Philip Landoff. Here together with Tom Jacobsson.

The multifunctional S3 cutting system facilitates a wide range of cutting processes, offering versatility and flexibility.

“Solving our peak demands”

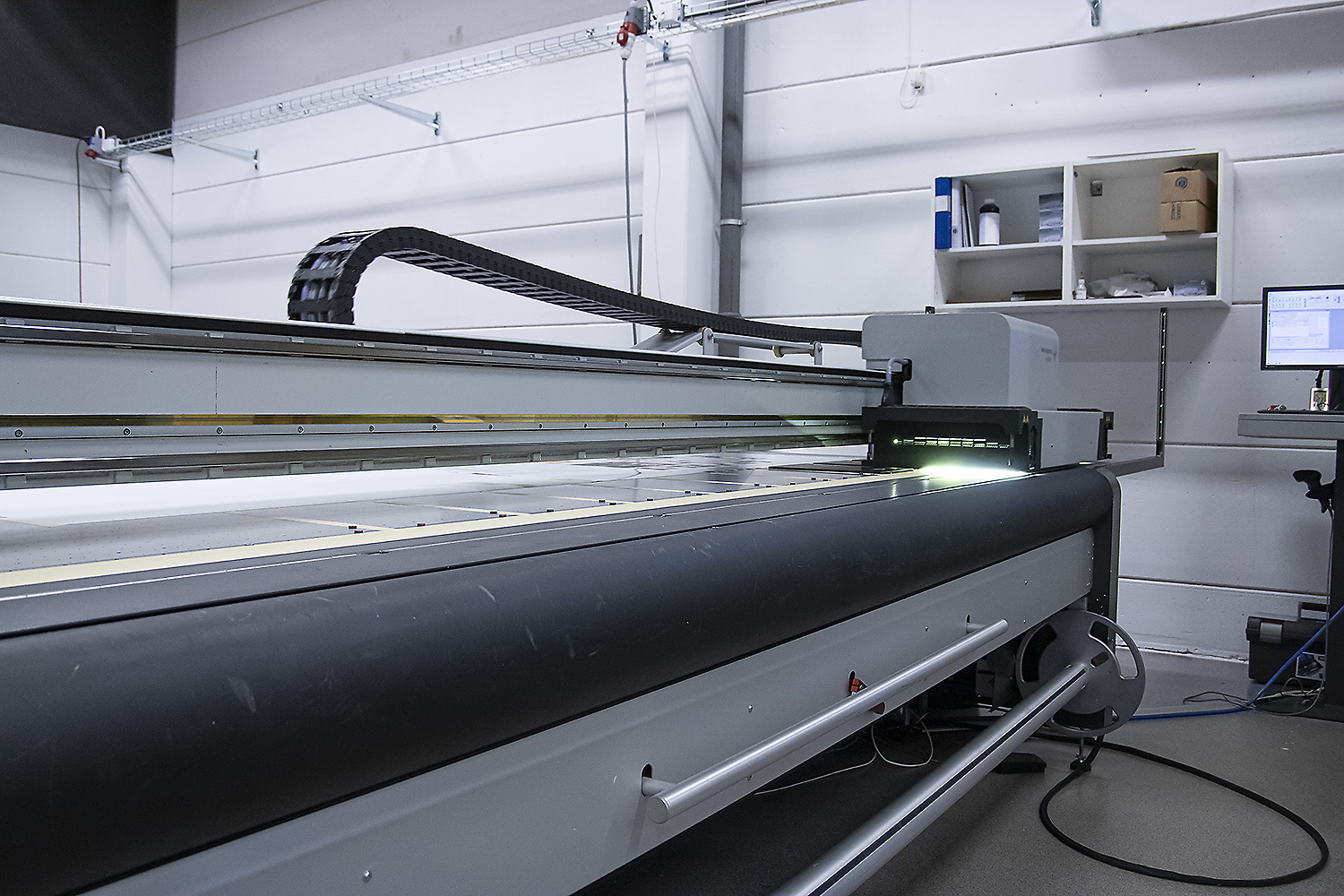

They’ve also upgraded to the Swissqprint Nyala 2 flatbed printer. The table measures 3.2 × 2 meters and features roll-to-roll capabilities. The rolls can accommodate widths of up to 320 cm or diameters of 36 cm. Compared to their previous flatbed printer, the new one operates at speeds 4-5 times faster.

“We don’t constantly run it at full capacity, but it significantly improves our ability to handle peak demands. Now, our focus is on minimizing downtime,” they explain.

The printing house has recently upgraded to the Swissqprint Nyala 2 flatbed printer.

The large-format printer from Epson frequently takes the lead in the machine park.

The combination of the flatbed printer and the cutter naturally provides increased capacity.

“With all three machines in operation, we can handle a significant volume of work. This places us among the larger competitors in the market.”

At the beginning of the production line, the company boasts two large format printers of the Epson SureColor 80600L model.

“We use the roll printer or the flatbed printer to apply ink. The flatbeds are ideal for hard materials, while soft materials are processed using our Epson printer.”

Post-processing tasks are carried out on the Zünd cutters, accommodating various materials based on the specific requirements.

“Each material undergoes cutting, trimming, cleaning, creasing, or milling as necessary. We can even engrave on them if needed,” they add.

The company has seen significant progress with its latest investments in the machinery.

“Although these are substantial investments, they have proven to be worthwhile,” they conclude.

Increased Production Capacities

The capacity expansion has significantly impacted the operations of the company in Motala. This enhancement enables them to handle and estimate larger volumes of work.

“We couldn’t manage this before. Additionally, the increased space plays a crucial role. Some routing tasks that previously took two days due to logistical constraints can now be completed in just one day because of our expanded workspace,” they explain.

Production has experienced the most substantial growth in recent years.

“We’ve made investments specifically to foster this growth. Our ability to produce large quantities in a short timeframe has improved significantly compared to before. Even with the new machines, we’re still adjusting. We often find ourselves thinking ‘this is a lot,’ only to realize that we’re processing it much faster than anticipated. We haven’t fully grasped the extent of our increased capacity yet,” they admit.

Graphic Profile specializes in producing campaign materials, which demand high volumes within tight deadlines. They now have the capability to address this task more effectively.

Abundant Space

The printing house relocated to new premises last autumn. Vintergatan in Motala hosts a vibrant graphic cluster, featuring companies like Inplastor, Sign Nordic, Motala Design & Dekor, and Screen & Serigraphy.

The new premises have plenty of space. Maybe even for new machine purchases?

Team of Installers

Currently, the business employs nine individuals. Four of them are installers, primarily working in the field. They not only assemble the company’s products but also provide assembly services for other companies within the industry.

“The larger companies don’t have their own installers. Therefore, we are part of assembly networks, covering Östergötland for some of them. This leaves about five of us here in-house for production, which is somewhat limited. Whenever possible, we provide support with one of the assembly teams based here,” explains the team.

On the factory floor, printers and post-processing equipment are located, while another spacious room is dedicated to car wrapping and storage.

Lukas Sundahl, who competes in the Porsche Carrera Cup with his Porsche, has his vehicle re-foiled at Graphic Profile. Although he finished second in the 2023 competition, he has clinched victory five times in the past.

Graphic Profile är ett av flera grafiska företag på Vintergatan i Motala.

New CRM Software

When Sign&Print pays a visit, a significant change is on the horizon. In just a few days, they will be up and running with the digital CRM program Omikai, designed to coordinate and clarify aspects such as quotes, orders, planning, time allocation, material needs, invoicing, and transportation.

“We’ve observed larger players than us switch to programs like this, and we’re not envious of them. While we’re not undergoing as extensive a transition as they are, it’s still a big deal for us,” they acknowledge.

The system aims to improve predictability.

“We’re transitioning from relying on vague estimations about production times to implementing a more precise digital planning process that we hope will be accurate. This will result in time savings, improved delivery reliability, and clearer delivery timelines,” they explain.

They also hope it will improve work-life balance for employees during production peaks.

“No one should have to work late on the last night; instead, we should be able to see in advance that we have a heavy workload, allowing us to start working on it a little earlier,” they emphasize.

Additionally, it will provide everyone with a clearer overview of tasks that need to be completed.

Network Importance

When Tom Jacobsson and Johan Gustafsson started the company, they were just two people. In 2009, they merged with another company. They began to specialize in foiling and assembling for larger clients such as Brand Factory, which had production facilities in Linköping and Farsta.

Graphic Profile produces a considerable amount of in-store material that they assemble. Currently, they are heavily involved in projects for one of the major gas station chains.

“We install ramps, color walls instead of painting them, put up pictograms and texts. We produce and send to other installers, but primarily, we handle a lot of the installations ourselves.”

Avoiding End Customer Theft

Initially, most of the customers were local for the printing house.

“Then we started to expand internationally,” says Tom with a touch of his Småland dialect.

He believes that one advantage for the business is that they often work as intermediaries and do not directly serve end customers.

“The advantage of being located in Motala is that we are not in Gothenburg trying to poach their customers, nor are we in Stockholm taking theirs. It’s quite reassuring to work with us because we are not actively competing in the larger market for our clients’ customers. I believe many perceive this as a significant advantage.”

Graphic Profile

Background: The company was established following the merger of William Text&Dekor and TJ’s Print and Product Labeling in 2009.

Location: Motala. It relocated to new premises in the autumn of 2023.

Staff: Nine individuals. Approximately half work in production, and the remainder are involved in assembly.

Revenue: Just over ten million with a profit of 750,000 (2022).

Main Production: Store promotion materials, foiling, large formats, signs, decals, and decor.