Published by Sign, Print & Pack Norway

Text & photo: Karin Karltun

Tine is Norway’s largest dairy cooperative, and among large milk tanks and production equipment for a variety of dairy products, there is an ever-so-small printing house.

Tine Dairies headquarters.

In newly built site at the main facility at Kalbakken in Oslo, advanced equipment has been set up for small-scale digital production of campaign material and other graphic products. Sign&Print has visited to hear about the advantages of having their own in-house printing house, and their latest investment, a cutting table from Zünd.

At the breakfast table, with the pancakes and in the porridge, you will find products from Tine Dairies in many Norwegian households. And while, among other things, the food packaging is produced by Tetra Pak and Elopak, the dairy group therefore has its own print house on its site.

The main print-shop at Kalbakken is not that small either, so it is important that you know where to go when you visit it. After criss-crossing through several corridors, we finally entered the printing area. Three employees work here, and one of them is Sverre Iversen, who is the department manager for the print house.

– We produce shop material, material for events and for the various departments at Tine. Also, there can be applications like decorative wallpaper, car decor and signs, and foils for floors and windows. Among other things, we have a huge amount of foil in the main building, says Sverre Iversen.

So what is produced here is not the same as what you traditionally find in the milk counter.

– We also produce many prototypes for out-testing things before they go to market. For this we use original cartons from Elopak to make it as authentic as possible, he continues.

One of the common jobs are to print materials for office use. Here are transparencies printed with HP Latex 2000.

The three employees at Tine’s print house, Sverre Iversen, Glen Burlin and Bedri Kocacenk.

A completely new investment

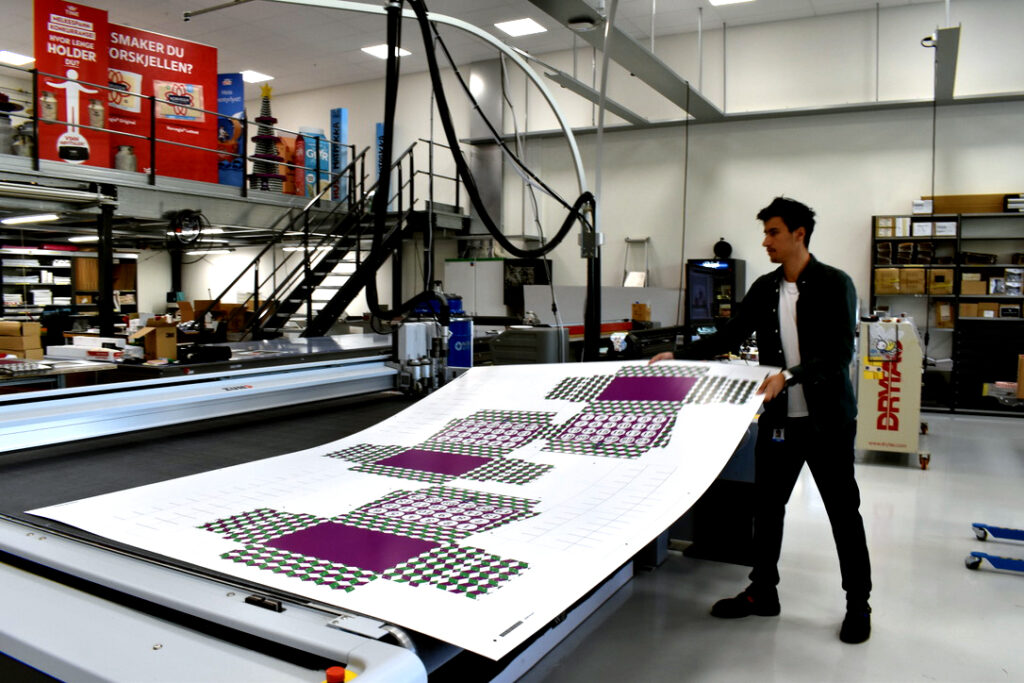

The somewhat secluded print house has been newly built for the purpose, and the trio moved in here in August 2022. On the floor are some large digital printers, including an HP Latex R2000 that they have bought from Antalis, and directly opposite you will find the latest addition; a cutting table from Zünd. And the location has been carefully revised, so that the workflow is as simple as possible.

– We bought the Zünd cutter for flat jobs that we used to carry out by hand. We were very good at this handwork, but it is not healthy for body and mind in the long run. And then it also became limited how large a volume we could handle, Sverre Iversen says.

They have bought a Zünd G3 2XL-1600. This cutter has a working surface of a whopping 2.74 by 1.6 meters and can cut media with a thickness up to 50 millimeters.

The work is data-controlled, and everything happens automatically after start-up. The material is held in place by various vacuum zones which are activated according to the size of the work. If several different cutting knives are needed, these are changed automatically, so that the operator can easily leave the machine during the work process.

Local Zünd technicians provide fast service

The cutter came to the printing house in 2022 but was purchased in the autumn of 2021, after careful assessments.

– We talked to a lot of people, and in the end we had two types to choose between. Then I spoke to an acquaintance at another printing company, and he had nothing but good things to say about Zünd. So that’s why we chose this one, says Sverre Iversen.

How do they work as a supplier?

– I would say that they are one of the better suppliers in my opinion. They are very professional in solving things quickly over the web. They are very ‘on’.

Now Zünd also had a technician in Norway

– Previously, the technicians came from Denmark and Sweden, but now they have got one in Norway, so that only makes matters even better, says Sverre Iversen.

The flatbed printer and the cutter are positioned directly opposite each other. Bedri Kocacenk and Glen Burlin work together.

The finished result of the advent calendar.

Bedri Kocacenk mainly works with sheet printing.

New opportunities

The new cutter has enabled production of many more types of jobs.

– Now we can produce more things inhouse, such as cutting thousands of magnets for, among other things, marking shelves. There are probably not many people who would be able to stand there for hours to cut something like this manually, and now we do this much faster without being burdened with monotonous work.

Glenn Burlin has just started cutting a cardboard box. It will become an advent calendar.

– The Zünd cutter makes a very big difference. Everything is faster now, and there are many good functions on the table that you can use when cutting things like this, he says. We also make very large cardboard products, such as pop displays.

And it is exactly this type of work that they devote a lot of time to at the printing house.

In-house is an advantage

Being a in-house printing company is quite obviously different from professional printing companies in several ways, as you only have one customer. But they still produce for several companies that are part of the same group, such as Diplom-Is and Fjordland. And if we run out of time, we can outsource the jobs to external manufacturers.

– We depend on our excellent partners in external printing houses if we feel that we do not have the capacity for an assignment, or if the volume is too large for us.

What does it mean for Tine to have it’s own printing house?

– For the organization, it is clearly an advantage that we can do things very quickly, but also that we have the opportunity to find quick creative solutions in close cooperation with the client.