Terma provides mission-critical solutions for the defense and aerospace industry

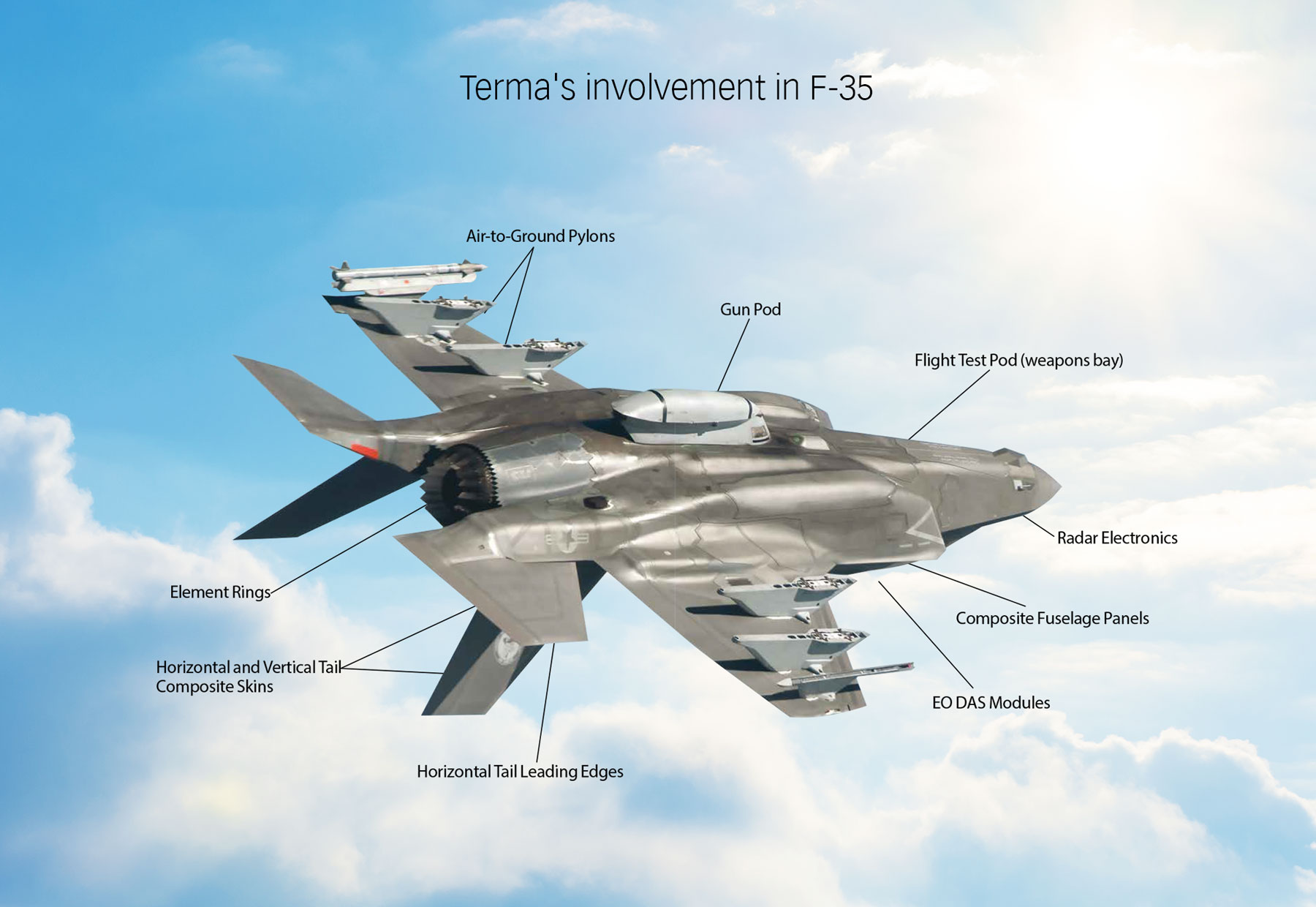

Denmark based high-tech Terma Group develops products and systems for defense and non-defense security applications; including command and control systems, radar systems, self-protection systems for aircraft, space technology, and aerostructures for the aircraft industry.

Terma works closely with national defense forces, public authorities, and international organizations around the world. Through these relationships, Terma has gained in-depth knowledge of and insight into their customers’ working environments and an equally deep understanding of their challenges and needs.

Terma leverer missions-kritiske løsninger til forsvars- og rumfartsindustrien

Den danske højteknologiske Terma Group udvikler produkter og systemer til forsvars- og sikkerhedsløsninger og -systemer; herunder kommando- og kontrolsystemer, radarsystemer, selvbeskyttelsessystemer til fly, rumteknologi og strukturdele til flyindustrien.

Terma arbejder tæt sammen med forsvar offentlige myndigheder og internationale organisationer over hele verden. Herigennem har Terma fået indgående kendskab til, og indsigt i deres kunders begrebsverden – foruden en omfattende forståelse af deres udfordringer og behov.

For the production of such high-tech equipment, Terma is dependent on reliable and efficient machinery. For cutting their composite materials, they use two Zünd G3 L-3200 cutters equipped with knives and ink-jet marking systems. The Ink-jet markings make it possible to trace the components in further processes.

Optimal utilization of their very costly materials is important. For this Terma uses efficient nesting software from Zünd which ensures a minimum of waste.

The video shows the cutting and marking of carbon fiber prepreg.

For at kunne producere udstyr på et så højteknologisk niveau, er Terma afhængig af pålidelige og effektive maskiner. Til skæring af komposit-materialer, har Terma to Zünd G3 L-3200 skæremaskiner udstyret med knive og inkjet-mærknings systemer. Inkjet-mærkningen gør det muligt at spore komponenterne i den videre proces.

Udnyttelse af det kostbare materiale er vigtigt. Til det bruger Terma en meget effektiv nesting software fra Zünd, som sikrer at så lidt som muligt går til spilde.

Videoen her viser hvordan carbon fiber prepreg bliver mærket og skåret.

Terma was established in 1949 and is headquartered at Lystrup, Denmark, with Danish facilities at Grenaa and in Copenhagen. International subsidiaries and facilities are based in the U.S. (Washington, D.C.; Warner Robins and Atlanta, GA; and Fort Worth, TX), the Netherlands (Leiden), Germany (Darmstadt and Berlin), UK (Harwell Oxford), Belgium (Brussels), UAE, India, and Singapore.

Terma is owned by the Thomas B. Thrige Foundation, Copenhagen, Denmark.