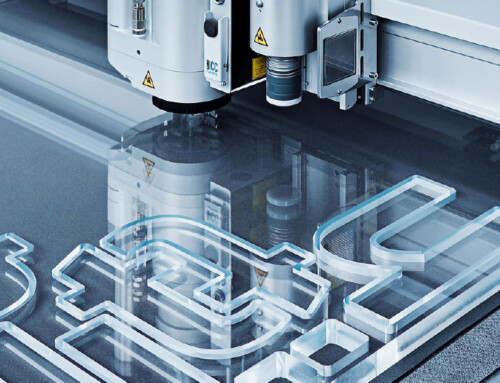

Now fully automated Zünd router bit changer (ARC)

The automatic router bit changer makes routing, polishing, and engraving more efficient and cost-effective than ever. It simplifies tool handling and significantly increase routing quality and efficiency. The router bits required for processing are automatically selected, clamped, initialized, and cleaned after use. This significantly reduces the time required for bit changes.

While the cutter is operating automatically with maximum efficiency, quality control is ensured at all times: the integrated initialization system ITI verifies the zero point after each tool fitting, thereby ensuring constant, precise routing depths.

In addition, the ARC optimizes production by helping to prevent operator error. Especially with routing jobs that require a variety of routing, polishing, and engraving bits, manual changes significantly increase the potential for error. The ARC makes mishandling router bit changes next to impossible.

The magazine of the ARC can accommodate eight router bits. In the standard configuration, six positions are available for regular bits and two for specialty bits, e.g. for v-grooving. A cleaning station adjacent to the magazine ensures that each bit is cleaned with compressed air before being returned to its slot. During routing, the ARC is automatically lowered and sealed with a protective flap to keep out dust and debris.

The ARC is available for all Zünd G3 systems with 50 mm beam clearance. Both available on new machines and as upgrade on existing installations.