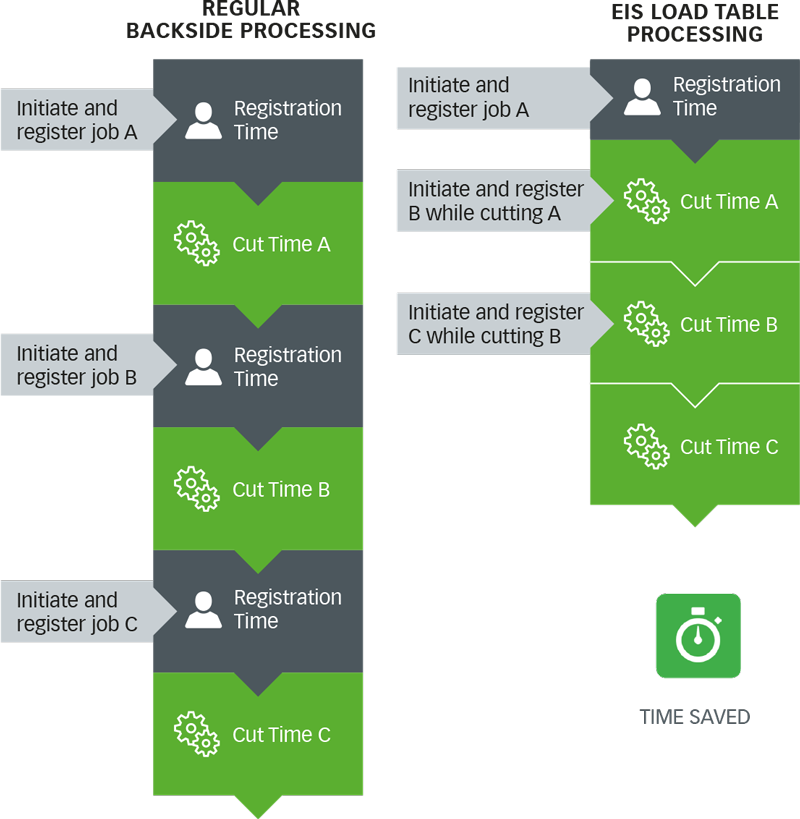

Eye in the Sky Load Table!

Accelerates cutting from backside

Game changing technology for backside applications

Increase productivity for applications, where cutting and creasing must be done from the backside. The EIS Load Table permits offline registration and job identification concurrently with production on the cutter. The operator can load and register the next sheet on the EIS Load Table while the cutter is producing. This benefits the operator, who becomes more efficient and flexible around the cutter. The smart way of working dramatically reduces production time for camera and/or edge registration and saves time not having to flip the board around.

Easy handling – high accuracy

The EIS Load Table is extremely simple to use. Just place sheet within the working area.

The optical method for registration ensures high cutting accuracy, and does not rely on print alignment, print repeatablilty and material edge quality.

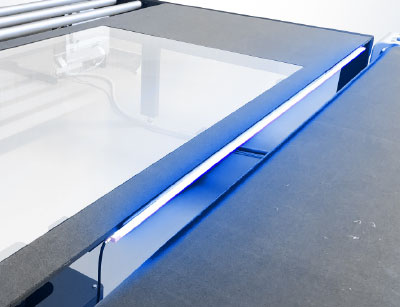

Transparent table

The rigid construction of the EIS Load Table includes a transparent plate made in hardened glass. Eye in the Sky camera technology captures fiducial and registration marks through this window.

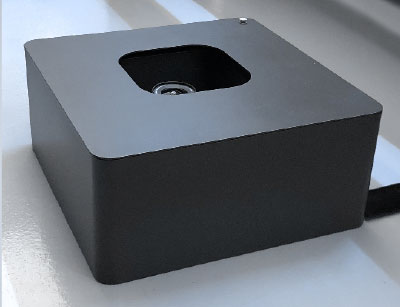

Eye in the Sky technology

An industrial and solid housing encapsulates the camera components – independent and shielded from cutter and Load Table vibrations.

Indicator light

Build-in light indicates status from the EIS Load Table and signals to the operator in case interventions are required.

Control pedal

Simple and ergonomic use of foot pedal for capturing next sheet/board. Alternatively launching from software interface is also possible.

Typical applications

A dedicated setup for creasing and V-cutting from the backside to produce POS/POP displays, packaging and structural designs.

Combine with robot for automation

Enrich your productivity with robot handling in combination with EIS Load Table. Expand production capacity and reduce on manual labor. Let a robot load sheets/boards to the EIS Load Table and unload from the cutter. Simple, integrated and fast.