Salling Group is Denmark’s largest retail group and includes a number of department stores and retail chains. Salling Group runs its own printing facility that produces facade signage and POS material for a total of 680 hyperstores, supermarkets, department stores, shops, coffee shops, and restaurants.

Every year, 300,000 m2 of sheet and foil material are produced. This equals approx. 42 football fields!

They can print 5-600 m2 of material per hour. Approx. 70-80% are finally processed on their two cutters.

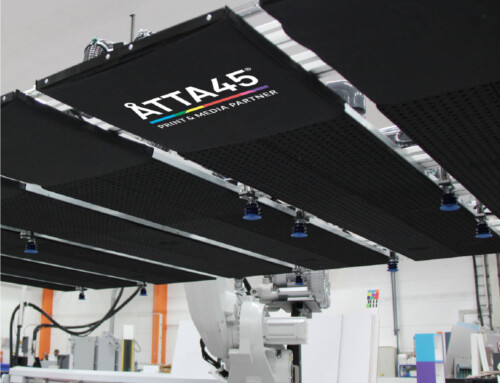

Salling Group has a Zünd G3 2XL-3200 and a G3 L-3200. Both with Eye in The Sky camera technology and Prepare-it! nesting software.

Salling Group er en danskejet dagligvarekoncern, der omfatter en række varehuse og butikskæder inden for detailhandlen. Salling Group har eget trykkeri, som producerer facade, skilte- og POS-materiale til ialt 680 hyperstores, supermarkeder, stormagasiner, butikker, caféer og restauranter.

Hvert år bliver der produceret 300.000 m2 ark- og foliemateriale – svarende til ca. 42 fodboldbaner!

De kan printe 5-600 m2 materiale i timen, hvor ca. 70-80% bliver efterbehandlet på deres to skæreborde.

Salling Group har en Zünd G3 2XL-3200 og en G3 L-3200. Begge med Eye in The Sky kamerateknologi og Prepare-it! nesting software.

In only a matter of five years, Salling Group has gone from analog graphic printing to being 100% digital. It has made a great difference to the handling of material and the improvement of indoor climate and the production environment.

På fem år er Salling Group gået fra analogt grafisk trykkeri til at være 100% digitalt. Det har gjort en verden til forskel på hvordan de håndterer materialer og på forbedring af indeklimaet og miljøet i produktionen.

Streamlined digital production

When you enter Salling Group’s production, you immediately sense the bustling busyness of the place!

Facade material, signage, and POS materials of all sorts are produced for Bilka, Føtex, Netto, Fætter BR, Salling, Starbucks, and Carls Jr. shops and departments around Denmark. Every week, new campaign material is sent out to each of them, so the production is always ongoing. It is a well-oiled machine and the two Zünd G3 cutters play a key role!

Willy Larsen and Jørgen Thobo-Carlsen explain:

“Before we bought our second Zünd cutter, our cutting capacity was under maximal pressure. The cutter received materials from both the flatbed printer and the three roll printers, and there was only one machine to cut everything. This meant our employees worked overtime for many months, and still, we could not keep up.

Therefore, it was both profitable and necessary to acquire a cutter more! One mainly cuts roll-material, the other primarily takes care of cutting sheets.”

Eye inThe Sky is an indispensable part of everyday life

“Both machines have EIS camera technology installed. When we bought our first cutter in 2016, we also invested in the first-generation EIS. With the purchase of the second cutter half a year ago, the old EIS was upgraded.

We cannot imagine cutting without it, and the system works perfectly.

In addition to EIS, we use Prepare-it to nest products before they are printed. The goal is to optimize as much as possible to save materials and time. ”

Strømlinet digital produktion

Når man træder ind i Salling Groups produktion, fornemmer man med det samme, at her er travlt!

Her bliver der nemlig produceret facademateriale og POS-materialer af enhver art til Bilka, Føtex, Netto, Fætter BR, Salling, Starbucks og Carls Jr. afdelinger rundt om i Danmark. De skal hver uge have tilsendt nyt kampagnemateriale, så produktionen er i gang hele tiden. Det er en velsmurt maskine, og de to Zünd G3-skæremaskiner spiller en central rolle!

Willy Larsen og Jørgen Thobo-Carlsen fortæller:

”Inden vi købte vores Zünd skæremaskine nummer to, var vi max presset på skærekapaciteten. Vi fik materialer til færdiggørelse fra både flatbedprinteren og de tre rulleprintere, og alt skulle skæres på samme maskine. Det betød rigtigt meget overarbejde til vores medarbejdere i mange måneder, og alligevel kunne vi ikke følge med.

Det var derfor rentabelt og nødvendigt at anskaffe en maskine mere! Den ene skærer fortrinsvis rullemateriale, den anden tager sig primært af opskæring af ark.”

Eye inThe Sky er en uundværlig del af hverdagen

”Begge maskine har EIS-kamera teknologi installeret. Vi fik første generation af EIS sammen med vores første maskine, som vi købte i 2016, og i forbindelse med købet af den nye for et halvt år siden blev den gamle opgraderet. Vi kan slet ikke forestille os at skære uden, og systemet fungerer helt upåklageligt.

Foruden EIS bruger vi Prepare-it til at neste produkterne inden de bliver printet. Det gælder om at optimere så meget som muligt for at spare materialer og tid.”

The Zünd machines have had an impact on the appearance of the stores

“For us, getting to know the machines and exploring their capacity, has been a process. With the Zünd cutters, we have been able to expand our product range and use materials that earlier we were unable to process. Ultimately, this has had an impact on the appearance of stores and customers’ shopping experience.

Previously we had to stick to cutting straight lines. Now, there are no limits to what we can cut. We can use advanced forms to increase the attention of our customers and make the advertising of the products more appealing and exciting.”

Easier to handle delicate materials

“In addition to an extensive paper and cardboard production, we run foil, foamed PVC, corrugated plastic, and Re-board on our cutters.

Changing to Zünd cutters has enabled us to work in delicate materials, such as corrugated plastic, which we use on a large scale for the Fætter BR toy-stores. Our challenge in past production was that the material was dented in the process. With the cutters using suction to hold down material, this is no longer a problem. This allows us to work with small orders as well as large ones.”

Less need for external help

“With the acquisition of the cutting machines, we have been able to keep almost all of our production in-house. Previously, we had to use external help to punch or cut materials that were outside the framework. External production took longer and was an expensive part of the production, so we are happy to keep it all in-house.”

Zünd maskinerne har haft en betydning for butikkernes udseende

”For os har det været en proces at lære maskinerne at kende og udforske kapaciteten af dem. Med Zünd maskinerne har vi kunnet udvide vores produktsortiment og bruge nye, hidtil uhåndterbare materialer. Ultimativt har det haft en betydning for butikkernes udseende og for kundernes købsoplevelse.

Hvor vi tidligere måtte holde os til at skære lige linier, er der nu ingen grænser for hvad vi kan skære. Nu kan vi bruge avancerede former til at øge blikfanget hos kunderne og gøre annonceringen af produkterne mere sælgende og spændende.”

Nemmere at håndtere blødere materialer

”Ud over en stor papir og karton produktion, kører vi folie, opskummet PVC, kanalplast og Re-board.

Skiftet til skæremaskiner har gjort det muligt for os at arbejde i blødere materialer, som f.eks. kanalplast som vi benytter i stor stil til Fætter BR-butikkerne. Vores udfordring var tidligere at materialet blev mast når det skulle holdes fast. Det er vi nu ude over med skæremaskinerne, da de suger materialet ned. Dermed kan vi arbejde med små ordrer såvel som store.”

Mindre behov for ekstern hjælp

”Med anskaffelsen af skæremaskinerne har vi kunne holde stort set alt vores produktion i huset. Tidligere måtte vi benytte ekstern hjælp til at få udstanset eller skåret materialer, som ikke lige faldt indenfor rammerne. Ekstern produktion tog længere tid og var et fordyrende led i produktionen, så vi er glade for at kunne holde det hele in-house.”

Why a Zünd cutter?

Before purchasing the first cutter in 2016, we spent a long time researching the market for the right solution. We needed the cutter to be reliable, and it was also an extra plus that Zünd was just around the corner for us, and the support close at hand. Our other machines are supported from abroad, which makes things a little more intricate.

“It is not often that we need support, as the cutters do not go down like many other machines.”

Our use of the support has primarily been getting help choosing the right knives for the various materials, and optimization of the cutting settings.

It’s nice that Zünd knows our production well, as the understanding between us is so much better.

Hvorfor en Zünd maskine?

Inden vi købte vores første skæremaskine i 2016, havde vi brugt rigtigt lang tid på at undersøge markedet for den rigtige løsning. Det var vigtigt at maskinen var driftssikker, og så var det et kæmpe plus at Zünd lå lige om hjørnet for os, og supporten derfor altid var nær. Vores øvrige maskiner bliver supporteret fra udlandet, hvilket gør tingene lidt mere besværlige.

”Det er ikke så tit vi har brug for support, da skæremaskinerne jo ikke går ned ligesom så mange andre maskiner.”

Vores brug af supporten har først og fremmest været i forbindelse med valg af knive til de forskellige materialer, og optimering af skæreindstillingerne.

Det er rart at Zünd kender vores produktion godt, da forståelsen os imellem bare bliver så meget bedre.